On May 5, the Long March 5B carrier rocket developed for China's manned space station project made its first successful flight in Wenchang, Hainan. In this launch mission, Weihua crane provided the rocket with high-precision hoisting and transshipment protection with advanced technology.

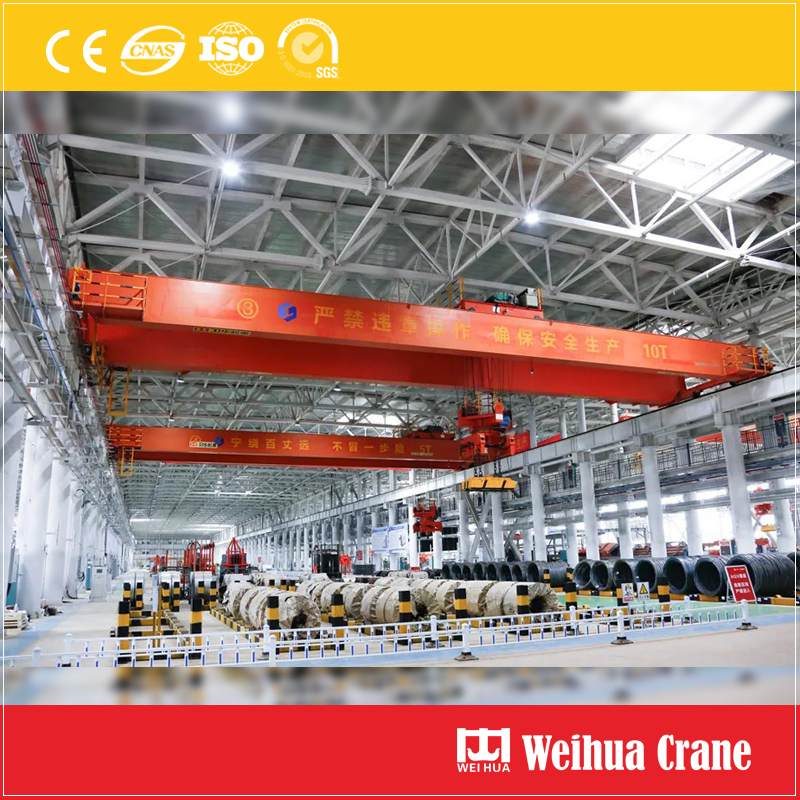

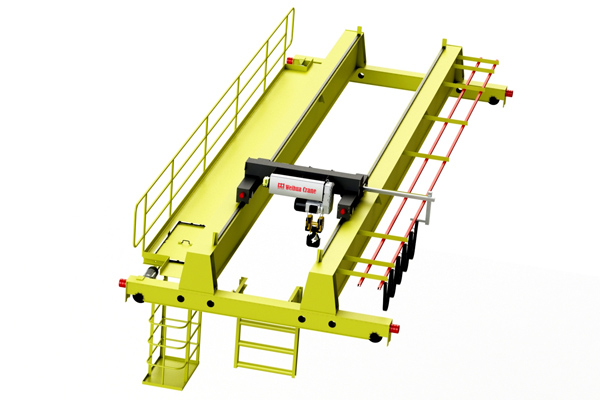

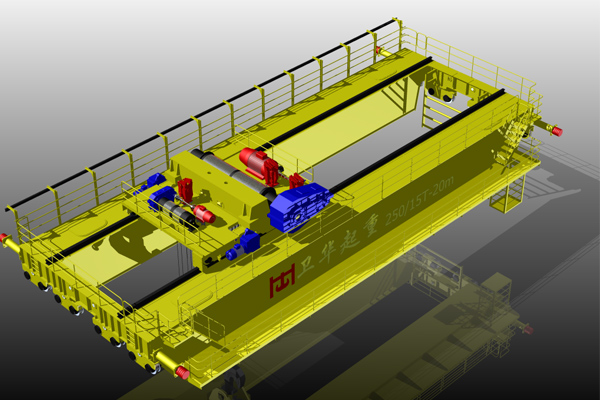

In Hainan Wenchang Satellite Launch Base, Weihua Group's over cranes undertaken the key link of rocket transfer and hoisting, and completed the handling, turning, and testing of rockets in the plant with high precision. Although the cranes are big and sturdy, their lifting accuracy reaches an astonishing 2 mm. The secret is that they have a sensitive Brain that can pass through the needle thread-equipped with anti-sway technology independently developed by Weihua, which can reduce the amplitude of swing by 95% and improve the stability and accuracy of the rocket during lifting.

Weihua lifting equipment has been serving aerospace engineering for a long time. It is the contractor of lifting equipment for 4 China satellite launch bases in Jiuquan, Taiyuan, Xichang, and Wenchang, helping the detector, the Long March rockets, the Mozi, and the Shijian 13 satellite successfully flew to the sky. In the journey accompanying the development of China's aerospace industry, Weihua Crane has accomplished all tasks excellently with the advanced lifting technology, excellent quality assurance, responsible professional attitude and perfect after-sales service, and has been unanimously agreed Praise and have won major contribution awards many times.

http://www.weihuacraneglobal.com/news/Weihua-Crane-Assist-Launching-of-Carrier-Rocket-Long-March-5B.html

Email: weihua@craneweihua.com

.jpg)

.jpg)

.jpg)

.jpg)