Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2019年8月29日星期四

Lattice Girder Gantry Crane Running in Crane Factory

In this video, you can see two lattice single girder gantry cranes (Email: weihua@craneweihua.com) running in Weihua Crane factory for crane beam manufacturing.

http://www.weihuagantrycrane.com/product/Lattice-Girder-Gantry-Crane.html

Single Girder Gantry Crane

This is an L type single girder gantry crane (Email: weihua@craneweihua.com) running in Weihua crane factory for crane beam fabrication and handling.

http://www.weihuacraneglobal.com/product/L-Type-Single-Girder-Gantry-Crane.html

2019年8月28日星期三

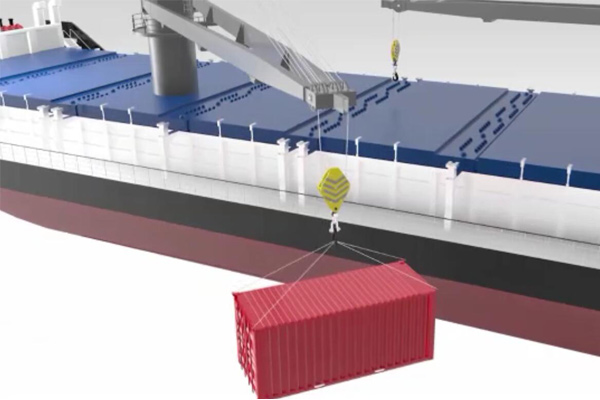

Marine Deck Crane / Weihua Crane

Marine deck crane is suitable for bulk carrier, container vessel, engineering ships which are voyaging international or domestic.

1. Built-in machine, electric, hydraulic, integrated system.

2. Fully hydraulic drive.

3. Self-diagnosis wave compensation system.

4. Luffing load horizontal movement technology.

5. Eight safety devices including torque limiter, etc.

6. Visible safety monitoring system.

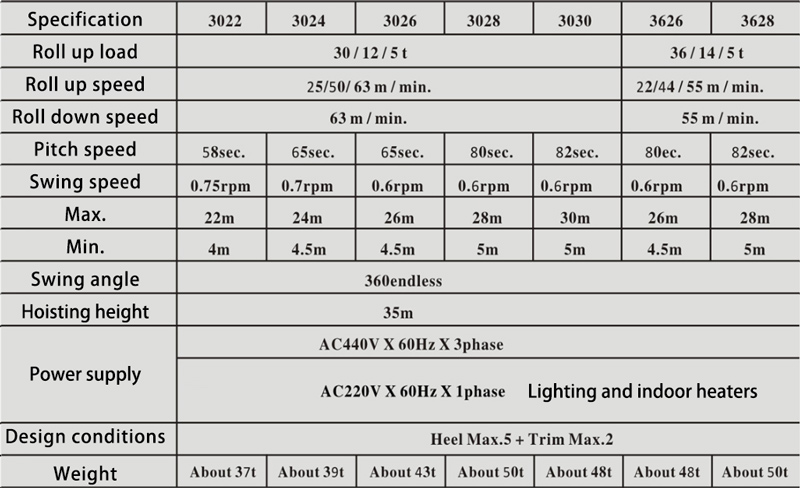

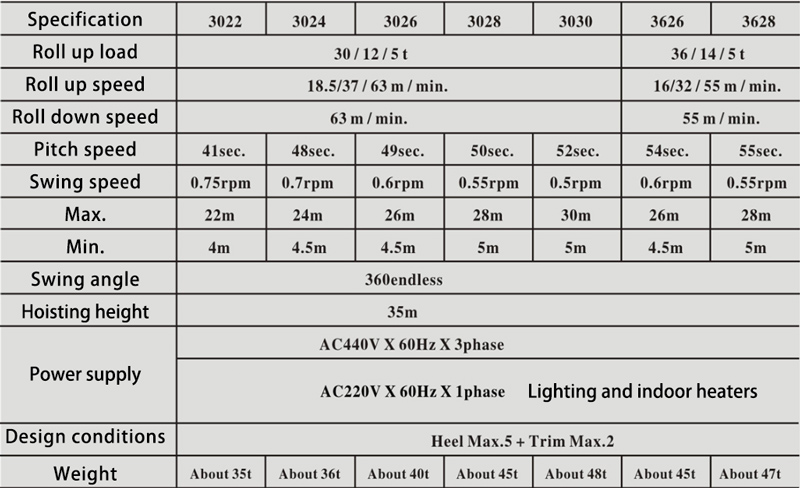

30t/36t Deck Crane Standard Speed:

30t/36t Deck Crane Fast Speed:

Weihua Ranks Top 500 of Chinese Private Manufacturing Enterprise

On August 22nd, the 2019 China Private Enterprises Top 500 Summit hosted by the National Federation of Industry and Commerce and the Qinghai Provincial Government was held in Xining, Qinghai. The summit focuses on the national strategic deployment and promoting high-quality development. At the meeting, the list of 2019 Chinese Private Enterprises Top 500 was announced, and the China Top 500 Private Enterprise Stressed Research Analysis Report was released. Weihua Group Co., Ltd. ranks No. 395 in the top 500 manufacturing enterprises of China's private enterprises in 2019. Since the National Federation of Industry and Commerce announced the list of the top 500 private enterprises in China in 2011, Weihua Group has been in this list for 9 years.

As a leading crane manufacturer in China, Weihua Group has always been committed to the development of innovation, green, intelligence, custom and network, and cultivating high-profit, high value-added and high-tech intelligent equipment. Weihua has confidence to lead the crane industry to towards glory.

.jpg)

.jpg)

http://www.weihuacraneglobal.com/news/Weihua-Ranks-Top-500-of-Chinese-Private-Manufacturing-Enterprise.html

Email: weihua@craneweihua.com

Email: weihua@craneweihua.com

2019年8月23日星期五

Rail Mounted Container Gantry Crane / Weihua Crane

Rail mounted container gantry crane (RMG crane) is mainly used to load, unload, move and stack containers in railway transship fields and large container storage yards. It is constituted by main girder, rigid and flexible outriggers, trolley travel mechanism, lifting mechanism, crane travel mechanism, electric system and operation cab.

.jpg)

This rail mounted container gantry crane can be 3 kinds based on operating type in storage yards: whose girders outreach at the direction of the single outrigger is called single cantilever crane and at the direction of the double outrigger is called double cantilever crane, and whose girders do not outreach is called non-cantilever crane. Users can choose different types depending on the different demands of yards, storage and transport ways of containers and vehicles (trucks or railway vehicles).

Features of Rail Mounted Container Gantry Crane:

1. Low lifting speed because of low lifting height. High crane traveling speed fits the requirement of the long-track containers storage yards' productivity. The spreader would go over the fourth/fifth container layer when the stack of containers is three/four layer and its lifting height depends on the requirements of storage yards

2. The trolley traveling speed depends on the span and the outreaching distance of both sides of the bridge. In the case of the span and outreaching distance is short, smaller trolley traveling speed and the productivity is advisable; otherwise, the trolley traveling speed could be accordingly increased to meet productivity requirement.

3. When the span is over 40 meters, the crane mechanism travels in a high speed, and both sides of outriggers would deviate because of the drag on each side is different. So there is a stabilizer equipped on this crane and electric system would keep both sides of traveling mechanisms synchronous.

4. Electrical drive-control system adopts thyristor speed regulating drive AC or DC control system to meet the higher need and accomplish a better performance of speed regulating and control. Or it adopts conventional AC eddy current speed regulating control system and AC stator voltage and speed regulating drive control system.

An electric braking that equipped with thyristor speed regulating drive AC or DC control system or AC stator voltage and speed regulating drive control system is usually used as the electric control system of a high speed crane traveling mechanism. Conventional AC eddy current speed regulating drive control system which depends on the brakes to shut down traveling mechanisms should be avoided in order to prevent the huge impact to whole crane.

Email: weihua@craneweihua.com

Grab Dredgers / Weihua Crane

Grab dredgers are used for dredging work in waterways, harbor pools and underwater infrastructure works. It is suitable for dredging mining mud, gravel, pebbles and cohesive soil, but not suitable for dredging fine sand.

Cross Digging:

The grab dredger is suitable for the cross digging. 5 anchor cables shall be arranged and length of the main anchor cable and tail anchor cable shall be 200m to 300m. Edge anchor cable should be set aside about 100m.

Downstream-Countercurrent Digging:

It prefers downstream digging compared with countercurrent digging. Countercurrent digging also can be adopted in case of low water flow rate or reciprocating water flows.

Grab volume: 18m3

Dredging depth: 50m in water, 10m above water

Grab dredger arm length: 30m

Working radius: 15-23.5m

Features of Grab Dredgers:

1. Visual Simulation;

2. Underwater visualization work;

3. GPS positioning, precise dredging control;

4. Consistent excavation depth;

5. Flat dig control to ensure the accuracy of 15cm flat dig.

http://www.weihuacraneglobal.com/product/Grab-Dredgers.htmlEmail: weihua@craneweihua.com

2019年8月18日星期日

Boat and Yacht Handling Crane / Weihua Crane

Yacht handling cranes, also known as boat handlers. It is widely used in water sports games, yacht clubs, navigation, shipping and learning, etc. It can transport different tonnage (32 tons - 1000 tons) of boats or yachts from the shore dock for on-shore maintenance, repair or launching of new vessels.

The boat and yacht handling crane includes the following items: main structure, traveling wheel block, hoisting mechanism, steering mechanism, hydraulic transmission system and electric control system. The main structure is N type, which can transfer the boat/yacht with height surpass crane's height.

According to different requirements of our customers, the boat handling crane can handle different tonnage boats or yachts (10T-800T) from the shore side, it can be used for the maintenance on the shore side or can put the new boat into the water. This yacht handling crane has soft and firm belt to lift the boat and yacht so that it will never hurt the surface. This crane also can put the boat in sequence quickly with small gap between each two boat.

Features of Yacht Handling Crane:

1. For the crane traveling, this crane can move in diagonal direction, this boat and yacht handling crane also can steer in 90 degree and put the boat in any designated position according to requirements.

2. This crane can be adjusted the width of the main girder according to the boat in case to handling different side boat.

3. This yacht handling crane is of low expense, high performance, easy to operate and maintenance and so on.

4. Low cost on the daily operation, it adopts the soft and firm belt to ensure there is no harm to the boat when hoisting.

5. This boat crane can make the boat in order quickly; it also can adjust the gap between each boat according to different condition.

Email: weihua@craneweihua.com

Rubber Tyred Container Gantry Crane / Weihua Crane

Rubber tire container gantry crane is employed to handle containers, boats/yacht, large component at the loading/unloading places and container yard. This rubber tyred crane is fitted with multiple hooking point's spreaders to meet the needs of different lifting situations. The whole crane can carry out 360° steering with flexible movement.

Full hydraulic drive for crane traveling mechanism and lifting mechanism with Step less speed change. The long traveling use hydraulic closed circuit with good transmission efficiency, less fault. There are safety indicator and overlord limiter to ensure safety of operators and products. All operation are controlled by CAN-BUS control.

.jpg)

Features of Rubber Tyred Container Gantry Crane:

1. Rubber tyred container gantry crane is usually called RTG for short, which is employed to stack containers in container storage yards. Rubber tyred container ganry crane is flexibly moved by its own rubber tires for transshipping containers.

2. Weihua rubber tyred container gantry crane is equipped with specialized spreaders to lift standard-sized 20GP, 40GP, 45HQ containers and hydraulic storage tanks.

3. The trolley and crane traveling mechanisms equip three-in-one reducer with convenient maintenance.

4. The tires of this container gantry crane can rotate 90°and move obliquely at 20° and 45°.

.jpg)

.jpg)

Full Set Rubber Tyre Gantry Crane Fixed at the Cargo Ship Deck

Email: weihua@craneweihua.com

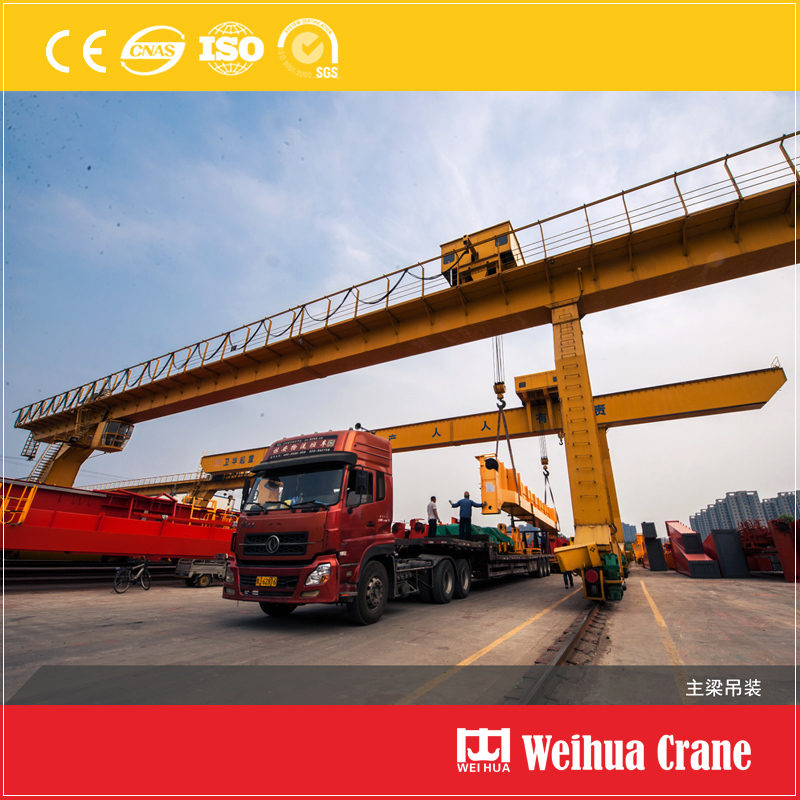

2 Gantry Cranes Lifting Crane Girder Synchronously

The video shows 2 single girder gantry cranes (Email: weihua@craneweihua.com) are working together handling a crane beam/girder synchronously in Weihua Crane factory. Weihua gantry cranes can be used for multiple cranes (2-4 crans) linkage operation.

http://www.weihuagantrycrane.com/product/RMG-Crane-for-Steel-Track-Handling.html

Warehouse E.O.T Crane

This is a single girder E. O. T crane (Email: weihua@craneweihua.com) in reducer warehouse. It is equipped with electric hoist.

http://www.weihuacraneglobal.com/product/Chinese-Standard-Single-Girder-Overhead-Crane.html

2019年8月14日星期三

Container Rail Mounted Gantry Crane / Weihua Crane

Features of Weihua Rail Mounted Gantry Crane for Container Handling:

1. U-type frame, double cantilever with rod, strong, light weight.

2. Large gantry span and width, continent container loading and unloading

3. 360° rotating spreader with excellent adaptability and efficiency.

4. Long Traveling Mechanism Assembly

5. Frame/Gantry Assembly

6. Trolley Assembly

7. Electrical Control System

8. All digital frequency conversion and PCL control technology

9. High Precision Sensor Data Acquisition Technology

10. Industrial computer data analysis and processing system

.jpg)

Rail-type container gantry crane is mainly consists of the steel structure, lifting mechanism, micro-transfer mechanism, spreader anti-sway system, crane travelling mechanism, container spreaders, electrical equipment, and other necessary auxiliary equipments.

The container rail mounted gantry crane adopts frequency conversion, PLC control system and CMMS fault detection system. Main standard reference: GB/T19683-2005, JT/T566-2004, and ISO standard of International Standardization Organization, European FEM, Japan JIS standard.

Features of Container Rail-Mounted Gantry Crane:

1. This crane can be used in inland terminals, container yard, rail freight station, coastal freight yard and frontier wharf.

2. Adopt dedicated container spreaders which can handle 20 feet, 40 feet and 45 feet containers.

3. Electrical drive system is full digital AC frequency conversion, PLC control speeding, CMS intelligent monitoring and management system, the running state real-time monitoring equipment.

4. The upper trolley can rotate 270 degree for easy load and unload.

5. Three-in-one reducer is adopted for long travel and cross travel, easy maintenance.

6. Safety protection: Anti-breaking shaft, wind warning, anti-tipping, etc.

Depending on the constitution of main girder, outriggers and anti-sway device, container rail mounted gantry crane can be divided into different types.

1. Double cantilever gantry crane has big room between its outriggers for containers to pass through. Usually opening widely at upper parts to form a shape of U and combining with the girder forming a shape of N.

2. Non-cantilever crane has a simple structure because of containers do not need to pass through the room between its outriggers.

Compared with ship-to-shore gantry crane, the trolley of Rail Mounted Gantry Crane travels at a lower speed and usually equipped without anti-sway stabilizer, while it will be equipped with anti-sway device if users need it for reducing operation stress and improving production efficiency. For rope type lifting mechanism, increasing the rope damp is a usual way to accomplish stabilization. And for rigid type lifting mechanism, its own rigid components are available to accomplish stabilization.

Email: weihua@craneweihua.com

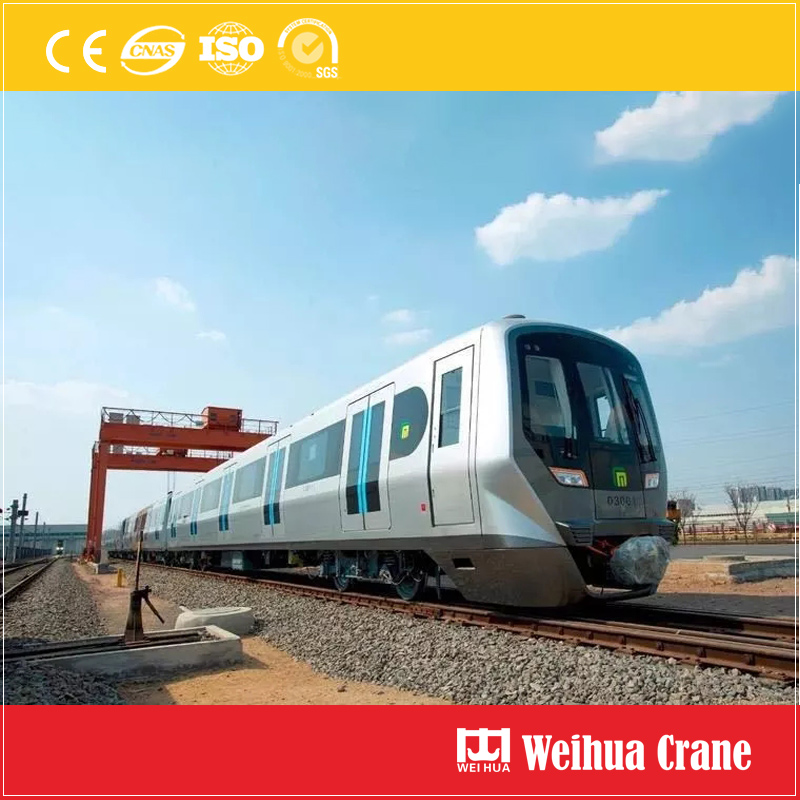

Gantry Crane for Maglev Train Handling / Weihua Crane

The Gantry Crane for maglev train handling is a Double Girder Gantry Crane for the installation and commissioning of high-speed 600km/h maglev trains, is responsible for the production and lifting work of the train project. The gantry crane has the characteristics of light self-weight, small wheel pressure, maintenance-free, stable operation, low noise, saving plant space, energy saving and environmental protection. Weihua provides all kinds of Project Crane, Container Crane, Overhead Crane, Electric Hoist and Crane Components, etc.

On May 23, China's 600 km/h high-speed maglev train launching in Qingdao. This is a big breakthrough of high-speed maglev technology in China. As an emerging high-speed traffic mode, high-speed maglev train has the advantages of high speed, safety and reliability, low noise, low vibration, large passenger capacity, punctuality and low maintenance.

In recent years, Weihua intelligent cranes are easily found in machinery, metallurgy, mining, electric power, water conservancy, aerospace, railway, port, petroleum, chemical and other industries, serving many large enterprises and key projects in China and overseas, such as launching of Shenzhou spaceships, Long March rockets, and Tiangong detectors successfully.

Why Weihua?

- 31 years' experience, 6800 employees.

- Weihua covers an area of 3, 420, 000m2 with a 60,000m2 workshop.

- Total 10 crane series with 300 kinds of products including annul output of 30,000 hoists and 6000 overhead & gantry cranes.

- 600 people R&D team, 494 patents, national level technical test center, CNAS laboratory and 2000 production & test equipment.

- With 15 subsidiaries, Weihua is located in China`s crane production base.

- Our products are exported to 110 countries such as Thailand, Malaysia, Russia, Mexico, Iran, etc.

- The company and products obtain the certificates such as ISO9001, 14001, OHSAS18001, CE, EAC, CUTR, SGS, BV, etc.

- Products are of world standard such as FEM, DIN and CMAA. Electrical systems and accessories use world-renowned brands such as: SEW, SIMENS, Schneider.

- Cooperation with Samsung, Port Authority of Thailand, ArcelorMittal, Malaysia Country Garden, CASC, etc.

Email: weihua@craneweihua.com

2019年8月13日星期二

Rotary Trough Crane for Steel-making Industry

This crane is a overhead crane (Email: weihua@craneweihua.com) with special spreader to handle rotary trough in steel making industry. The spreader can lift, transport, rotate the metal scrap trough.

http://www.weihuabridgecrane.com/product/Rotary-Trough-Bridge-Crane-for-Steelmaking.html

Single Girder Overhead Crane at Production Workshop

This is a single girder overhead crane (Email: weihua@craneweihua.com) with electric hoist running at Weihua Crane production workshop.

http://www.weihuacraneglobal.com/product/Chinese-Standard-Single-Girder-Overhead-Crane.html

2019年8月7日星期三

Gantry Crane for Railway Construction / Weihua Crane

The gantry crane for railway construction is specially designed for the concrete span beam/bridge moving and transport for railway construction. Users can use 2 cranes 500t (450t) or 1 crane 1000t (900t) with 2 lifting points to handle railway beam.

| Gantry Crane for Railway Construction |

This railway construction gantry crane consists of main girder, rigid and flexible supporting leg, travelling mechanism, lifting mechanism, electric control system, hydraulic system, driver room, railing, ladder and walking plat.

Features of Gantry Crane for Railway Construction:

1. Rubber tire type and rail-mounted type;

2. Hydraulic driven of walking, steering and lifting;

3. Walk straight, oblique and rampage;

4. Good adaptability, high working efficiency, small space occupied;

5. Special spreader mainly used for lifting and transporting large concrete beam/bridge;

6. 2 cranes, 2 trolleys with max lifting height 30m;

7. The max wheel load is 22t when lifting 900t stuff;

8. 90° shift for rail type crane to achieve horizontal or vertical walking;

9. 4 points for lifting and 3 points for balance to ensure even stress of the steel wire rope ;

10. Accurate positioning for stuff lifting down;

11. Hydraulic push for trolley to realize various lifting and save the cost;

12. For the 4 hoists, it can be single use or combine use of 2 or 4 hoists while the hardware and software are interlocked for operation safety.

Precast Beam Erecting Machine for Railway and Highway

Email: weihua@craneweihua.com

Gantry Crane for Highway Construction / Weihua Crane

This gantry crane for highway construction is employed to lift the concrete beam or bridge on to the supports of highway construction. It consists of girder longitudinal flat car, girder components, support system, crane transverse, longitudinal shift system, hydraulic system, electric control system, etc.

This highway construction crane can be rail type and step type. The rail type crane is mainly used for lifting of beams with length not more than 30m. While the step type crane need no rails, which has no pressure and damage to the highway beam/bridge because the legs can be landed on the supports.

| gantry crane for highway construction |

With the high-speed development of highway construction, Weihua is developing various highway cranes adapting to the different working and use requirements such as skew bridge, curved bridge, Dislocation Bridge, heavy beam, variable beam, double-direction construction, construction in tunnels, etc.

Features:

1. Horizontal operation landing the beam in place at one time;

2. Suitable for the construction of inclined(curved)bridge;

3. Light weight, convenient and quick transportation, installation and removal;

4. Safe and reliable work, small longitudinal cantilever deflection;

5. The legs are not landed on bridge deck when longitudinal moving, reducing the pressure on the beam/bridge deck.

Beam Erecting Machine for Viaduct Construction

Email: weihua@craneweihua.com

订阅:

博文 (Atom)