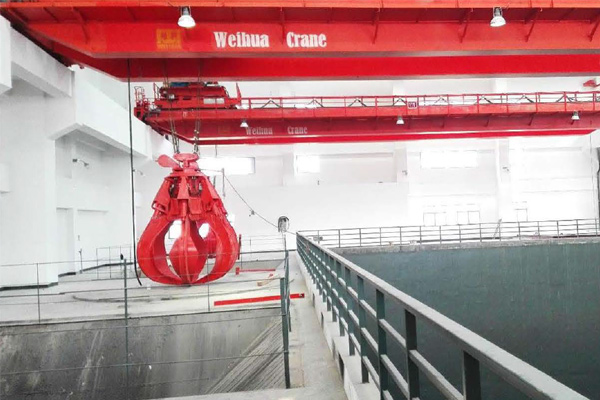

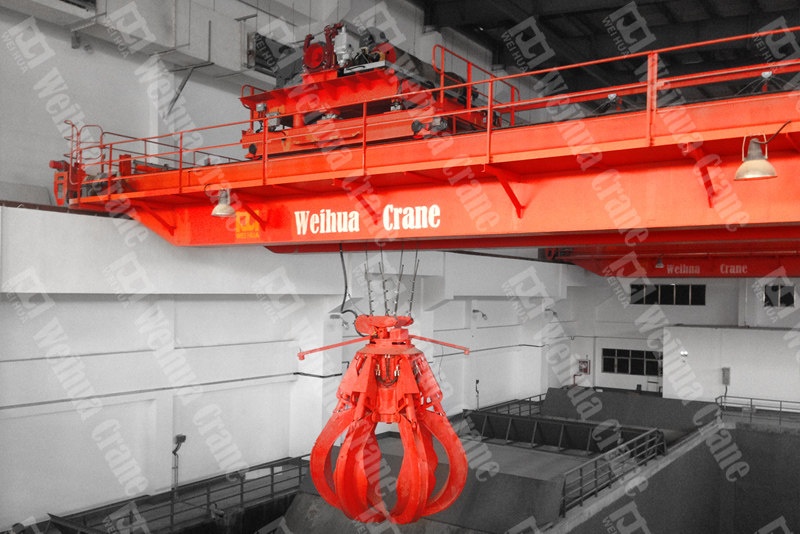

The overhead crane for garbage disposal is with a garbage grab, which is an import equipment in city waste incineration plant. Overhead crane for garbage disposal is installed over the garbage pit for garbage charging, transport, mixing and weighing. This garbage disposal crane can be manual, semi-auto and fully auto type, carrying out automatic grabbing, automatic repeat feeding, automatic repeat dumping, and automatic parking.

Manual Type:

Operator control the crane with the linkage console.

Semi-Auto Type:

The grab operation is manual control, and the auto controlled part includes the moving to charging port, weighing and charging.

Fully-Auto Type:

Once the crane receiving the charging signal from the charge port, the crane starts to do every move automatically, moving to the garbage, lower the grab, grabbing the waste, lifting the waste, moving to the charging port, weighing, charging, and returning the position. It will repeat the same motion automatically.

Capacity t/d

|

800

|

1,000

|

1,200

|

1,600

|

2,000

|

2,400

|

Lifting Weight

|

5

|

6.3

|

8

|

10

|

12.5

|

16

|

Grab Volume m3

|

3~4

|

4~5

|

5~6

|

6~8

|

8~10

|

10~12

|

Basic Operation:

1. Feeding. Grab and feed Fermented garbage into waste incinerator.

2. Lifting and transport. Lift and transport the waste near the discharge door to avoid blocking the discharge door. Control the quantity of garbage in the waste pit to keep the inventory within 3~5d.

3. Mixing. Mix the garbage to extract water content and shorten the fermentation time, as well as keep safe of incineration.

4. Fetching. Fetch non-flammable objects in the pit.

5. Weighing. Weigh the garbage before being dump into the incinerator.

Features of Garbage Disposal Overhead Crane:

1. High lifting height with anti-sway operation.

2. Real-time dynamic measurement.

3. Grab status monitoring, fault diagnosis alarm and report statistics.

4. Adapt to harsh working conditions: high temperature, Humidity, more Dust and Gas corrosive.

5. Heavy work load: average 8,000h working time per year, High load rate, high work frequency.

6. Reliable work: less failed, guarantee smooth production.

.jpg)

http://www.weihuacraneglobal.com/product/Overhead-Crane-for-Garbage-Disposal.html

Email: weihua@craneweihua.com

Email: weihua@craneweihua.com

.jpg)

.jpg)

.jpg)