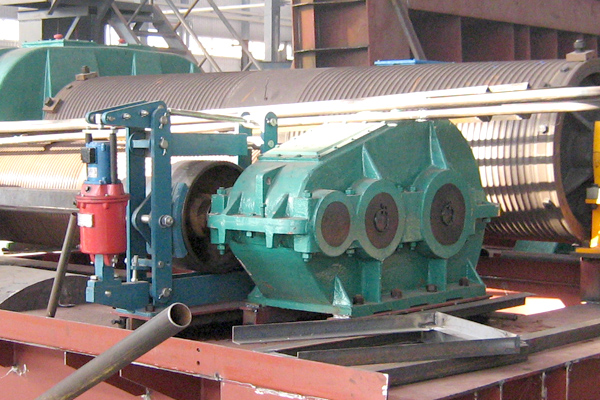

Crane brake is an important parts for Overhead Crane or Gantry Crane, which can decelerate and stop the running of a crane.

|

| Crane brake |

1. Application: Crane brake is for the moving parts deceleration.

2. There are 2 types: friction brake and non-friction brake.

3. Crane brake is mainly constituted by brake pad, brake arm, brake wheel and brake releaser.

4. To reduce the braking torque and the size of brake frame, the brake is usually installed on the high-speed shaft. To meet the needs of high safety for large machinery, like mine hoist and elevator, the brake should be installed on the low-speed shaft which next to the working parts the large machinery.

https://www.weihuacraneglobal.com/product/Brake.html

Email: weihua@craneweihua.com

.jpg)

.jpg)

.jpg)