|

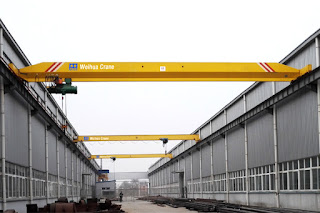

| Electrolytic aluminum cranes |

Most of the countries and enterprises are using large prebaked troughs because the through is of high current intensity, high degree of automation, low energy consumption, high single tank yield, and meets the requirements of environmental regulations. Aluminum electrolytic production can be three categories: side-mounted anode rod self-baking trough, upper plug anode pole baking trough and prebaked anode slot.

Bridge Crane for Electrolytic Aluminum is composed of feeding mechanism, slagging mechanism, the anode replace mechanism, shelling mechanism and aluminium discharging mechanism.

Email: weihua@craneweihua.com