Downshop conductor is a device that supplies power for bridge crane traveling. It is composed of sheath, conductor, collector and some auxiliary components.

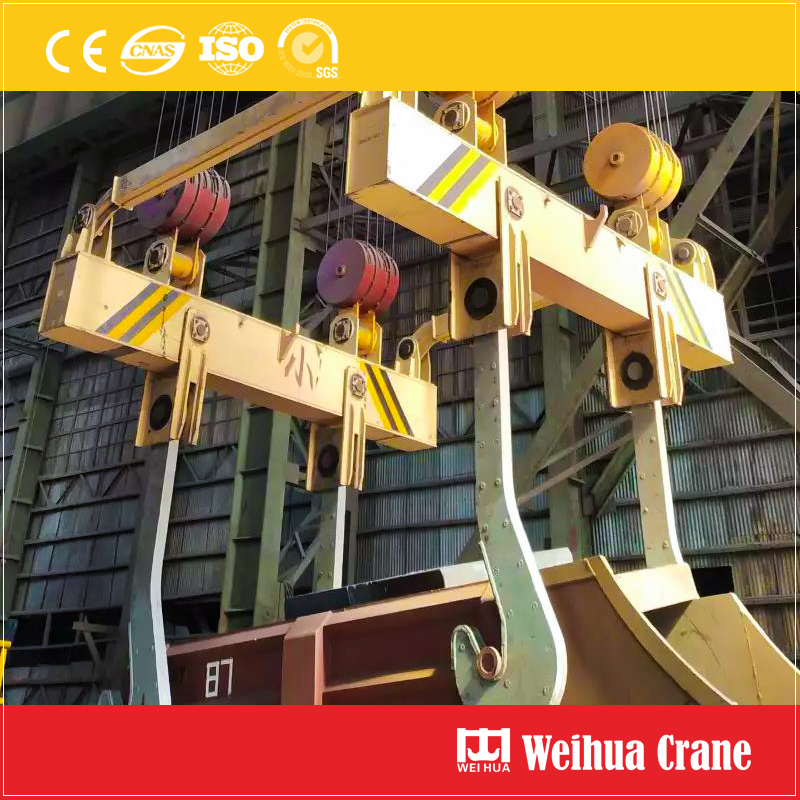

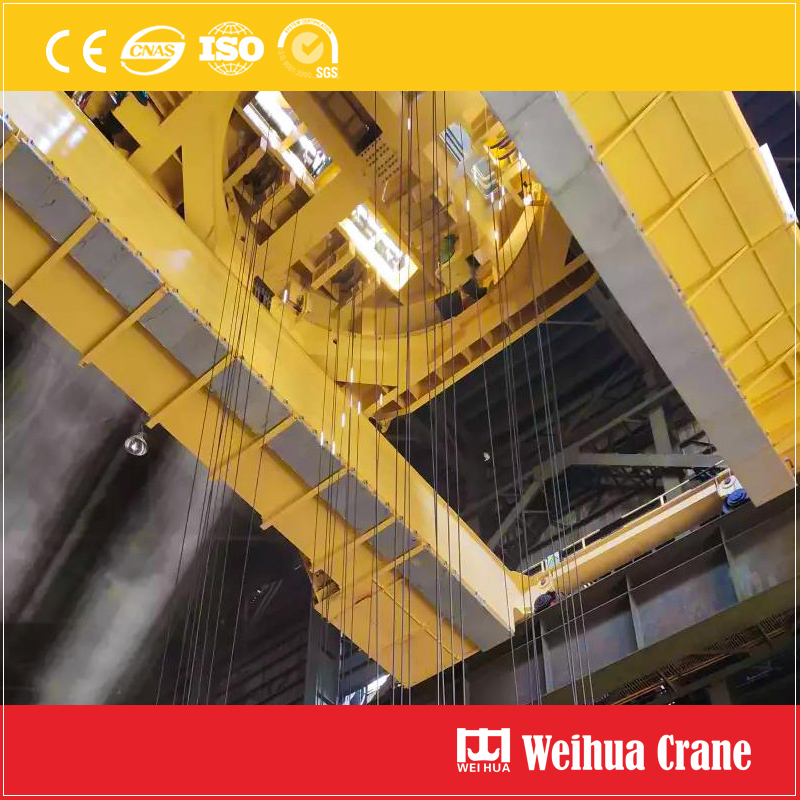

In order to facilitate the installation, the downshop conductor is usually installed on the track supporting beam. Take the unipolar combination downshop conductor installation as an example, there are 4 conductor bars, and the arrangement is easy to interfere with the crane walker attachment or main girder, as shown in the following figure:

In order to avoid the interference between the conductor and the crane, it is suggested to use the following 3 ways for installation:

1. Bending bracket for installation can effectively avoid interference problems. Bending height H can be determined according to the actual installation, it is recommended not less than 200mm.

2. The bracket is installed below the track bearing beam, and the sinking height H can be determined according to the actual installation, it is recommended not less than 200mm.

3. Adopt side installation.

No matter what kind of downshop conductor, it must be combined with the size of the plant and crane installation.