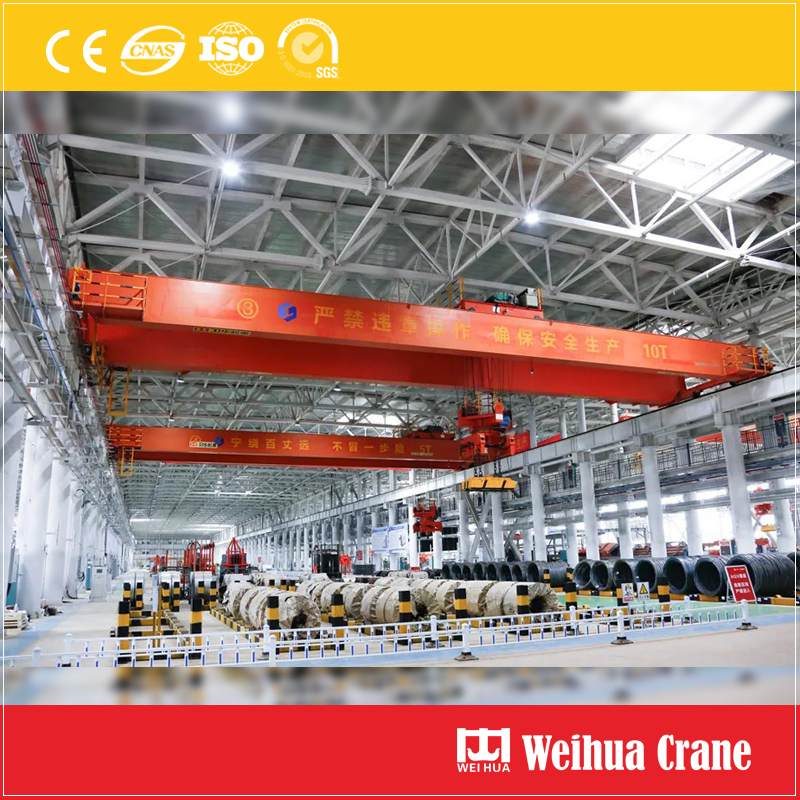

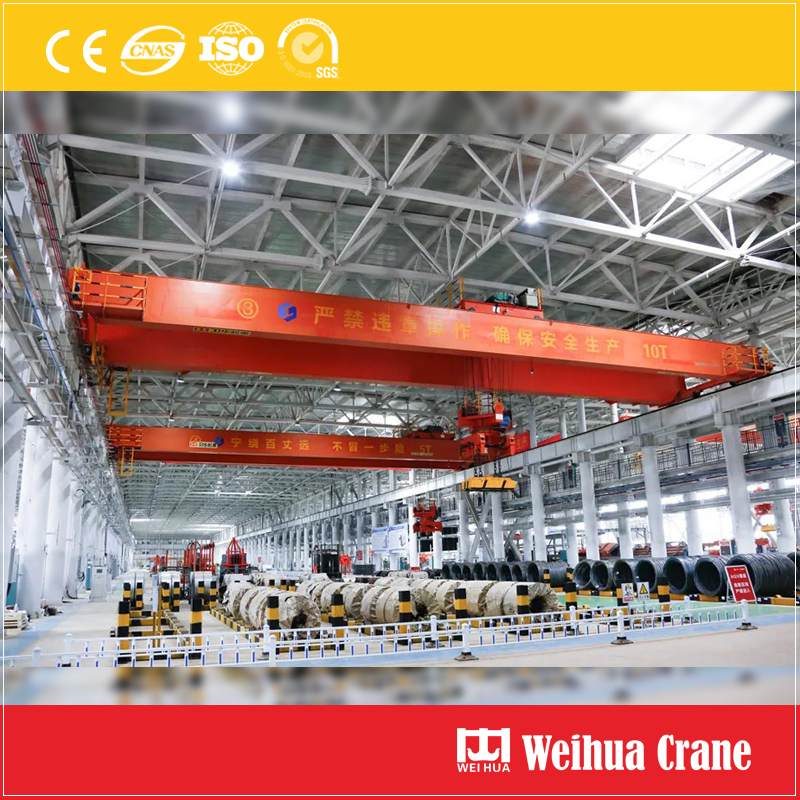

With China Manufacturing 2025 plan developing, unmanned factory is growing in large numbers. Weihua intelligent material handling equipment are also increasing. Now Weihua takes you to have a look at an unmanned plant in Guangxi Province. The images show the real-time working of Weihua's multifunctional intelligent unmanned crane for handling steel bar.

The Guangxi Engineering Technology Research Center adopts big data management and integrated applications, making it the premier unmanned factory in the construction industry.

Weihua intelligent unmanned magnet crane operation is an important part of the deep combination of Internet + smart manufacturing in the construction industry.

Features:

1. Automated systems developed by Weihua independently, with electric anti-sway system and automatic precise positioning functions;

2. Spreader replacement: Automatically replace the spreader according to the task;

3. Automatic lifting out and lifting in: (1) Into warehouse: Automatically identify the material unloading truck to the raw material storage area according to the list; (2) Out warehouse:

According to the loading task, it can automatically feed to the corresponding feeding point;

4. Transshipment: Automatically transfer finished semi-finished materials to the transfer point or AGV according to the transfer task;

5. Laser scanning: After the truck is put into place, it will automatically scan to identify incoming materials, and send out positioning coordinates to realize automatic unloading.

The multifunctional intelligent unmanned magnet crane is just a microcosm of the intelligent and high-end industrial manufacturing. Weihua will continue to increase its innovation and R&D to provide more intelligent handling equipment and solutions for various industries to help more intelligent unmanned plants.

Email: weihua@craneweihua.com

WhatsApp: +86 15093392066

.jpg)