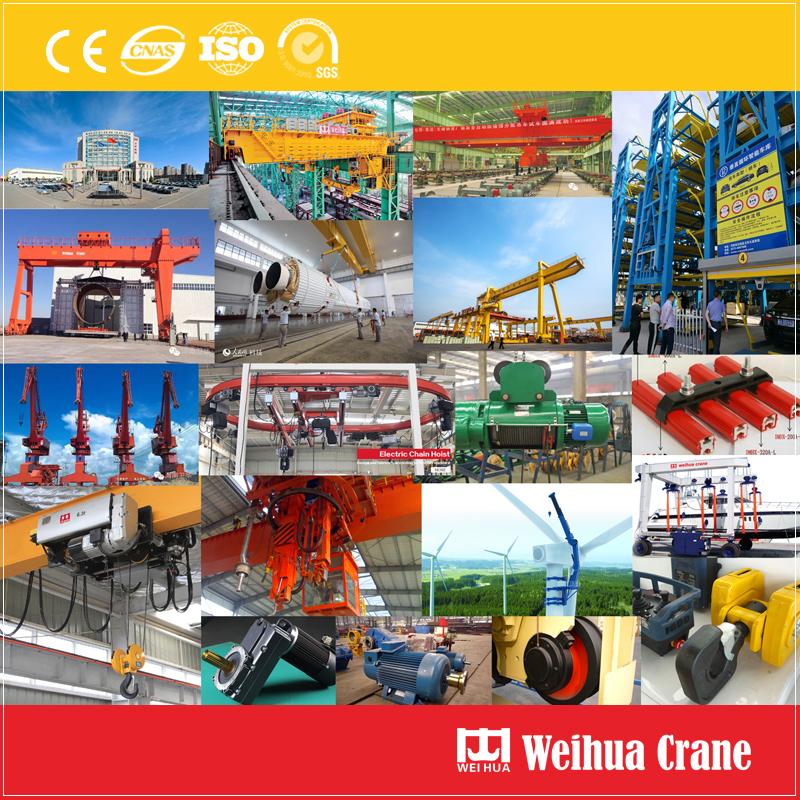

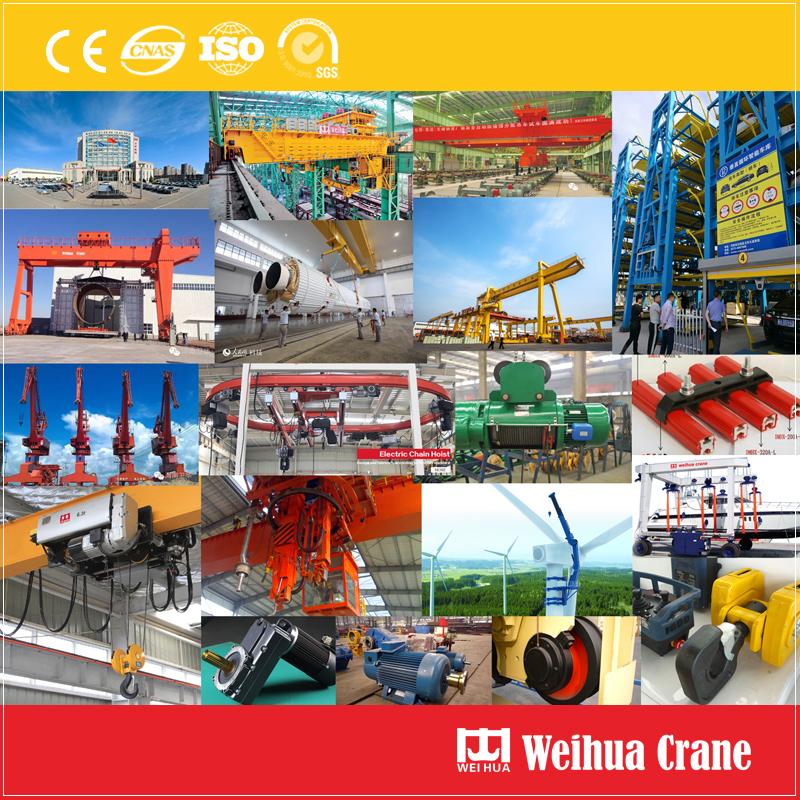

On August 14, seven

large-capacity cranes including a 180-ton

metallurgical bridge crane, a 90+90-ton

semi-gantry crane, and a 100-ton overhead crane were shipping to Kazakhstan, serving for a steel group project.

These metallurgical cranes are designed in accordance with the FEM standard. With modular design and modern computer technology, these cranes are of highly automation, intelligence and high-tech, for the production site with a large temperature difference.

180-ton Metallurgy Crane Technical Features:

1. This crane adopts a new rigid bridge structure with four girders, four rails and double trolleys, and the working level reaches A8;

2. The self-weight is reduced by 10%, the height is reduced by 25%, and the width is reduced by 25%; the product can be applied to the ambient temperature of -40°C to +60°C;

3. The new type of festoon cable power supply device that is resistant to high temperature radiation can operate reliably under the condition of high temperature radiation.

Technical Features of 90+90 ton Semi-gantry Crane:

1. This crane is a special material charging semi-gantry crane for steel mills. The lifting capacity of the crane is 90+90t, the lifting height is 24m, and the working level is A8;

2. The product has been newly designed for the problems of limited production space, high risk factor of tilt-pulling and hoisting during feeding, and excessive wire rope tilt-pulling angle;

3. It adopts the structure of 3 girders and 4 rails, and 2 independent lifting mechanisms are designed on each trolley, equipped with a special four-point gantry hook spreader, and the two lifting mechanisms can realize the function of hopper dumping and feeding through their independent actions;

4. Finite element optimization check calculation of the overall structure, simulate the actual operating conditions of the crane, and reduce the dead weight and the wheel pressure by 10%;

Email: weihua@craneweihua.com

WhatsApp: +86 15093392066