2. Widely used in transmission equipment of mining, metallurgy, chemical industry, building material and light industry, etc.

3. The crane reducer should meet the mechanical strength needs when it's used in cranes.

4. Crane reducer mainly used in mechanism of lifting, traveling, rotating and amplitude.

5. The needs of suspension-suit-type gear reducer which is installed in traveling mechanism are small volume, light weight and compact structure; and its output end should be Internal spline which is directly installed in wheel shaft, input end should pass through a coupling and be connected with brake motor by flange; and its top should have holes for pin shaft and buffer device to fix on frame.

6. Crane motor and converter-speed-regulating motor for metallurgy are squirrel-cage rotor motor. Squirrel-cage rotor motor could meet the needs of different working conditions, such as frequent starting, braking, overload, reversing, over speed, collision and vibrating. And it also could meet the need of working under invert control, to realize soft start and four-quadrant operation.

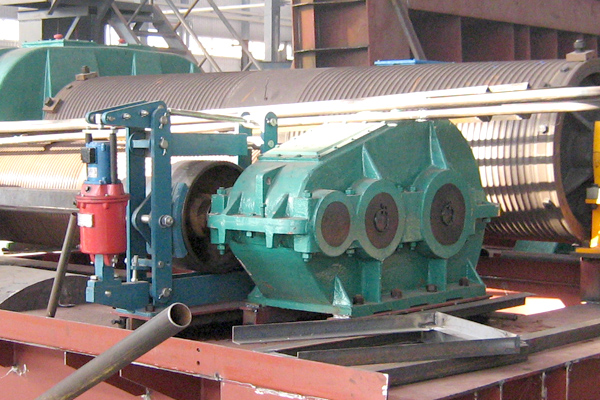

| Crane reducer |