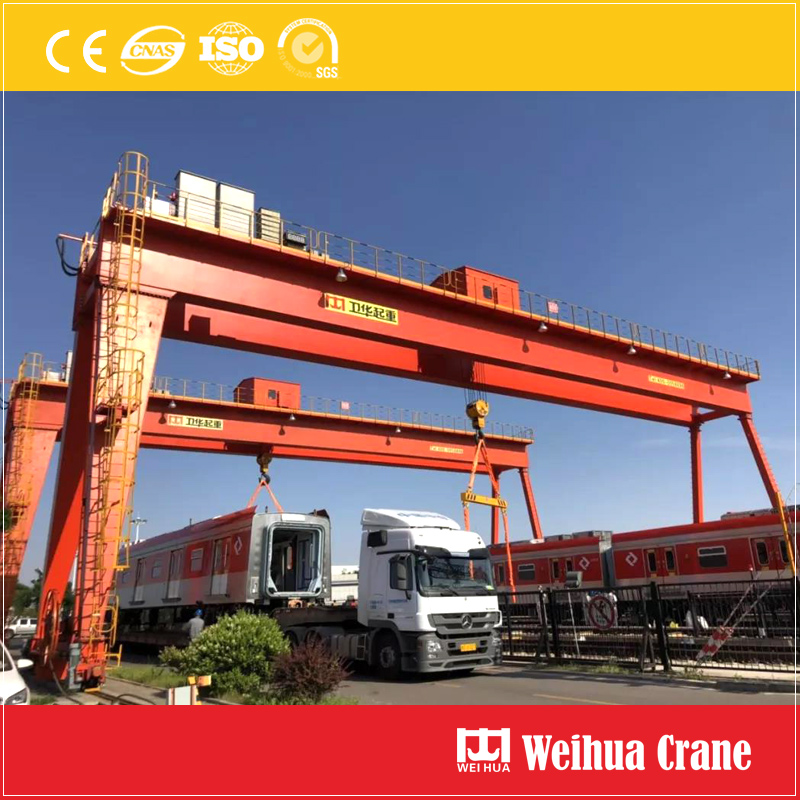

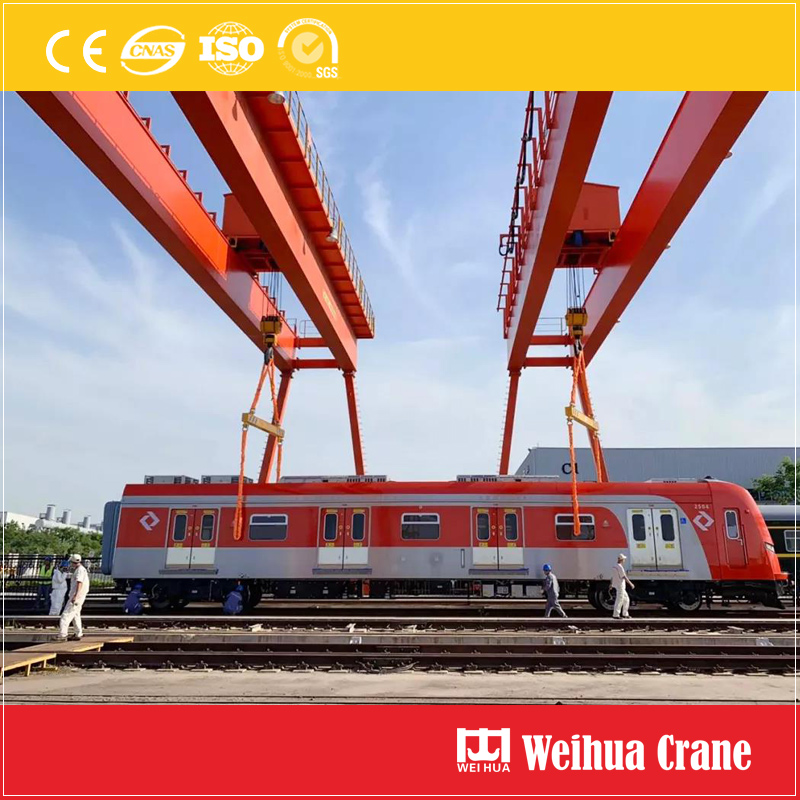

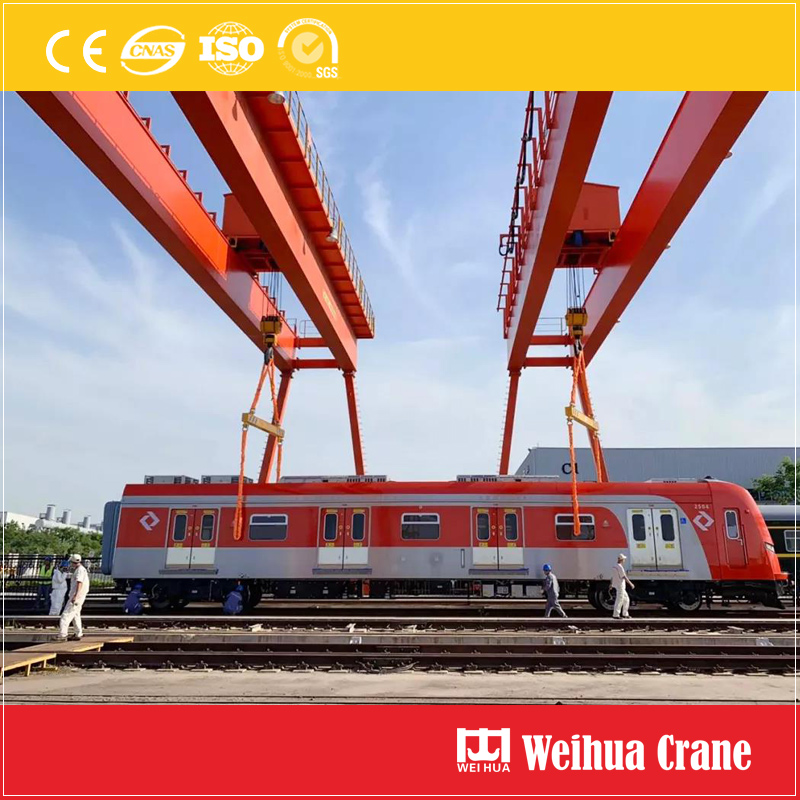

On June 3, the first train of CRRC project was officially launched in Brazil. There are a total of 64 urban rail vehicles of this project, which will be used to equip the first airport-urban line in South America.

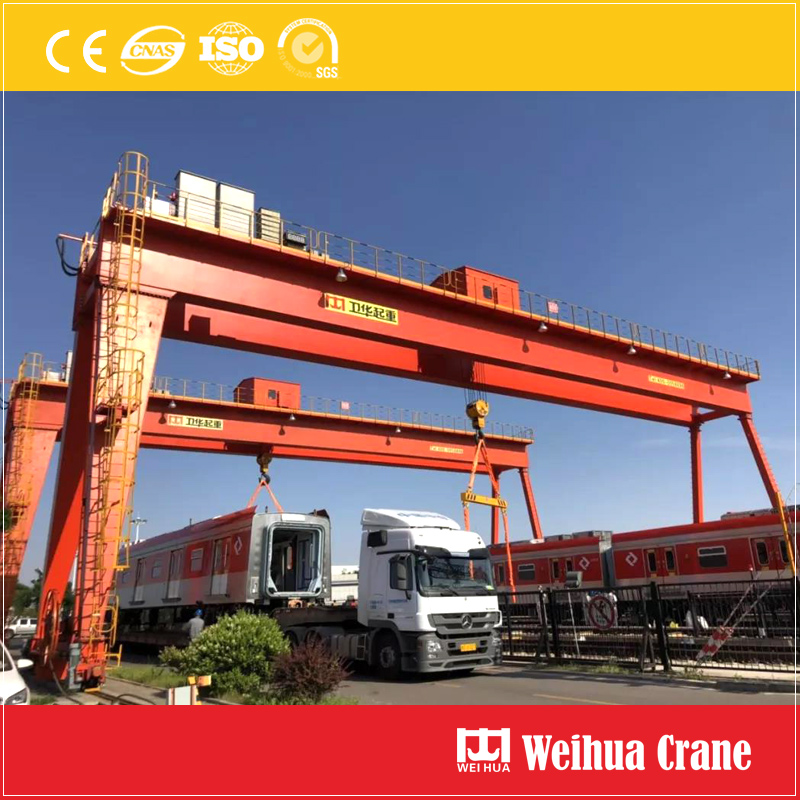

Weihua provides 2 new gantry cranes to service the assembly task of the trains of Line No. 13. The 2 gantry cranes complete the assembly test run with perfect match and precise positioning, and continue to serve the follow-up train assembly work.

The 2 gantry cranes serving this project is a new type gantry crane independently developed by Weihua. It is with lightweight design, modular design, uses new materials and new technology, and adopts the wireless linkage control system.

Features:

Light self-weight, small wheel pressure and reliable performance.

The trolley has a good appearance, excellent design and simple structure.

Direct-coupled mechanism, fast transmission and high efficiency.

Frequency control, stable braking and no impact.

Freely switch of ground control and remote control, easy to operate.

Two gantry cranes can be used alone or in linkage use.

Wireless communication detection, data transmission is safe and reliable.

Sound and light alarm reminder, fault diagnosis, intelligent safety monitoring.

Dedicated database and big data cloud platform services to realize remote operation and maintenance service application of gantry crane, track and optimize product operation status in real time, and improve equipment operation and maintenance efficiency and product service value.

Weihua has become an important supplier of CRRC, and wireless linkage gantry cranes are frequently used in many projects.

Weihua leading products are widely used in machinery, metallurgy, railway, aerospace and other industries, serving thousands of large enterprises and China key projects, and exported to 129 countries.

.jpg)

Email: weihua@craneweihua.com

WhatsApp: +86 15093392066

.jpg)

.jpg)