Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2021年2月2日星期二

Weihua Metallurgical Crane Reference

2021年2月1日星期一

LDA Speed Regulator

Crane speed regulator Model LDA is new type drive device for 5t electric single girder crane, it's an improved type of Model LD1. It has simple structure, small size, less noise, beautiful appearance, safe, reliable, smooth running, simple installation and maintenance, large starting torque, and able to be started frequently.

.jpg) |

| Crane speed regulator Model LDA |

Application: LDA speed regulator is a drive device of cranes.

.jpg)

Speed Regulator Features:

1. LDA speed regulator is a new type drive device for 5t single girder crane, it's an improved type of LD1.

2. Simple structure, small size, low noise, beautiful exterior, safe, reliable, running smoothly, easy for installing and maintaining, large starting torque, and able to start frequently.

3. Its first stage closed gear is replaceable for the needs of different transmission ratio.

4. 20, 30, 45, 60, 75m/min, five different speed mode to meet requirements of users.

.jpg)

https://www.weihuacraneglobal.com/product/LDA-Speed-Regulator.html

Email: weihua@craneweihua.com

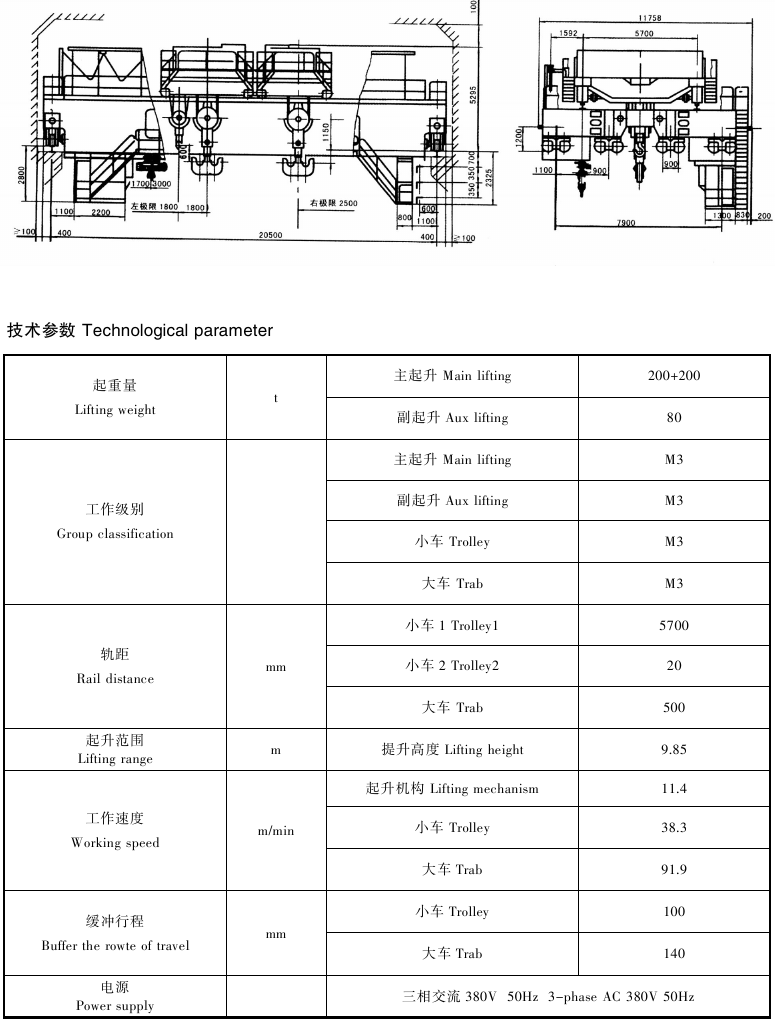

Overhead Crane with Double Trolley

Overhead crane with double trolley is an overhead bridge crane with 2 separated lifting mechanism. Different from the 1 trolley with 2 hooks (main hook for large capacity and deputy hook for small capacity), commonly the 2-trolley (each trolley can be also with main and deputy hooks) have the same capacity. People use 2-trolley mechanism for special working conditions.

|

| Overhead crane with double trolley |

The double trolley overhead crane can be used at power plant, metallurgy plant, steel plant, workshop, warehouse, papermaking, shipbuilding, etc. Capacity: 5+5t; 20+20t; 100+100t; 150+150t; 160+160t; 200+200t; 300+300t, etc.

Features:

1. The whole crane adopts frequency conversion and PLC control, which has stable lifting, small impact and less noise;

2. The trolley adopts European-standard design with compact structure, overall processing of trolley frame with high assembly precision;

3. The bridge structure finite element analysis makes the structure more optimized and more reasonable;

4. The components are durable and maintenance-free, equipped with hardened surface reducer, welding reel, rolling pulley and forged wheel;

5. Fast on-site installation without welding works;

6. CTS electrical modular system, convenient maintenance;

7. The whole crane is equipped with safety monitoring system and crane electric correcting device, and reserves interfaces of electrical intelligent anti-sway, intelligent jog, automatic positioning, remote monitoring and other interfaces.

.jpg)

https://www.weihuacraneglobal.com/product/Overhead-Crane-with-Double-Trolley.html

Email: weihua@craneweihua.com

TAG: Overhead Crane with Double Trolley

Specification

2021年1月28日星期四

Annealing Furnace for Metallurgy EOT Crane Trolley

Weihua build a big Annealing Furnace (size: 16m*8m*6m) for big crane parts heating and Annealing. This video shows a 320t metallurgy EOT crane trolley heating and annealing process.

Email: weihua@craneweihua.com

Mobile/WhatsApp/Wechat: +86 150 9339 2066

Intelligent Overhead Crane for Graphite Eelectrode Grouping and Loading&...

2021年1月24日星期日

Variable-frequency Drive

Variable-frequency Drive, VFD, is used to control AC crane motor by variable-frequency technology and microelectronic technology to control the power control equipment of AC crane motor through changing the motor-working power frequency. Crane Variable-frequency Drive helps the motor realize soft-start.

.jpg)

1. Application: Variable-frequency Drive for Control AC motor

2. Utilizing variable-frequency technology and microelectronic technology. That makes the Variable-frequency Drive able to control the power control equipment of AC motor through changing the motor-working power frequency.

3. Energy saving and operation accuracy improving.

4. Overcurrent, overvoltage and overload protection.

5. It helps the motor realize soft-start.

.jpg) https://www.weihuacraneglobal.com/product/Variable-frequency-Drive.htmlEmail: weihua@craneweihua.com

https://www.weihuacraneglobal.com/product/Variable-frequency-Drive.htmlEmail: weihua@craneweihua.com

One-Stop Warehousing Logistics Solution

With the development of the warehousing industry and the rise of the online business model, smart warehousing has become an important concern for many e-commerce businesses. In order to reduce manpower allocation and save warehouse space, intelligent stacking cranes came into being and became one of the core equipment of intelligent storage. Based on the customer's market orientation, Weihua has successfully developed and manufactured warehouse stacker crane system, which can effectively ensure the safety of operators.

|

| Warehouse stacker crane |

The stacker has a rated load of 1.5t, and each pallet can carry equipment with a volume of 1.2m (length) * 1.2m (width) * 0.7m (height). The basic shelf has 28 columns, 7 rows, 8 layers, a total of 1568 cargo spaces, and a total load of 2352t.

Warehouse stacker crane has strong applicability and wide application:

The warehouse stacker has strong applicability and can be used in production workshops, large retail beverage supermarkets, and warehouse storage of pharmaceutical companies. It suitable for various industries such as chemical industry, textile, auto parts, electronic products, supermarket warehouse, etc.

Systems:

1. Crane system: crane positioning system, anti-sway system, human-computer interaction HMI, crane remote control, wireless network settings, background server and crane body control, etc.

2. Warehouse management system: WCS management and WMS management, code scanning device, warehouse management system software, video monitoring system, wireless and wired network system, production docking MES interface.

3. The safety and warning system of the storage area: safety management of the working area of the crane, safety management of the ground sidewalk, safety management of the vehicle passage, various safety management indicators, alarms and safety barriers, etc.

.jpg)

Save power and improve efficiency:

1. The suspended stacker is mainly used in conjunction with the shelf, and is convenient to move during use, can save power, and save the occupied area of the stacker at the same time.

2. The automated 3D warehouse stacker brings great convenience to the logistics transportation industry and the large-scale warehousing industry. The stacker can not only improve the efficiency, but also reduce the damage rate of the goods. The stacker can protect the surface of the goods from damage to the greatest extent in the process of working.

Hoisting Mechanism | ||

Capacity | t | 3 |

Hoist Speed | m/min | 1.5~15 |

Working Duty | M5 | |

Max. Lift Height | m | 18 |

Stacker Forklift Speed | No Load m/min | 60 |

Full Load m/min | 30 | |

Power | Kw | 22+3 |

Power Supply | AC 3P 380V 50HZ | |

Traveling Mechanism | |||

Trolley | Crane | ||

Gauge | m | 2.5 | 20.2 |

Travel Speed | m/min | 3.8~38 | 5~50 |

Work Duty | M5 | M5 | |

Stroke | mm | 35 | 60 |

Max. Wheel Load | KN | 135 | |

Rail Track Specification | 60*40 | P43 | |

2*1.1 | 4*2.2 | ||

Power | Kw | 36 | |

https://www.weihuacraneglobal.com/case/One-Stop-Warehousing-Logistics-Solution.html