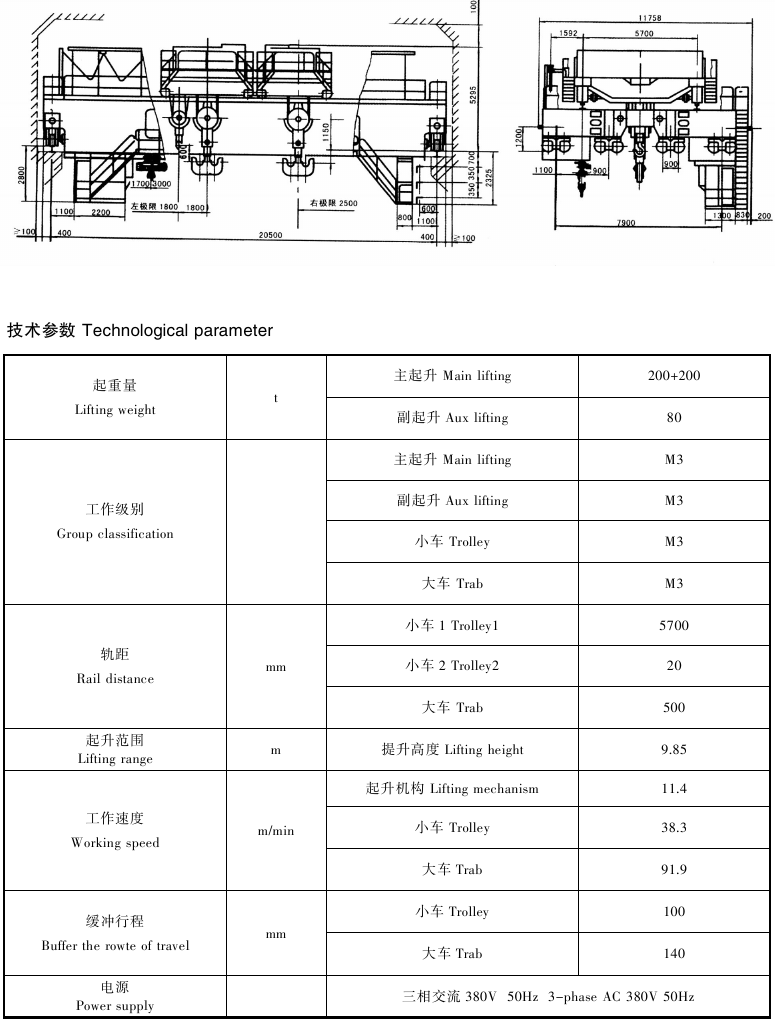

Overhead crane with double trolley is an overhead bridge crane with 2 separated lifting mechanism. Different from the 1 trolley with 2 hooks (main hook for large capacity and deputy hook for small capacity), commonly the 2-trolley (each trolley can be also with main and deputy hooks) have the same capacity. People use 2-trolley mechanism for special working conditions.

Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2021年2月1日星期一

2021年1月28日星期四

Annealing Furnace for Metallurgy EOT Crane Trolley

Weihua build a big Annealing Furnace (size: 16m*8m*6m) for big crane parts heating and Annealing. This video shows a 320t metallurgy EOT crane trolley heating and annealing process.

Email: weihua@craneweihua.com

Mobile/WhatsApp/Wechat: +86 150 9339 2066

Intelligent Overhead Crane for Graphite Eelectrode Grouping and Loading&...

2021年1月24日星期日

Variable-frequency Drive

Variable-frequency Drive, VFD, is used to control AC crane motor by variable-frequency technology and microelectronic technology to control the power control equipment of AC crane motor through changing the motor-working power frequency. Crane Variable-frequency Drive helps the motor realize soft-start.

.jpg)

1. Application: Variable-frequency Drive for Control AC motor

2. Utilizing variable-frequency technology and microelectronic technology. That makes the Variable-frequency Drive able to control the power control equipment of AC motor through changing the motor-working power frequency.

3. Energy saving and operation accuracy improving.

4. Overcurrent, overvoltage and overload protection.

5. It helps the motor realize soft-start.

.jpg) https://www.weihuacraneglobal.com/product/Variable-frequency-Drive.htmlEmail: weihua@craneweihua.com

https://www.weihuacraneglobal.com/product/Variable-frequency-Drive.htmlEmail: weihua@craneweihua.com

One-Stop Warehousing Logistics Solution

With the development of the warehousing industry and the rise of the online business model, smart warehousing has become an important concern for many e-commerce businesses. In order to reduce manpower allocation and save warehouse space, intelligent stacking cranes came into being and became one of the core equipment of intelligent storage. Based on the customer's market orientation, Weihua has successfully developed and manufactured warehouse stacker crane system, which can effectively ensure the safety of operators.

|

| Warehouse stacker crane |

The stacker has a rated load of 1.5t, and each pallet can carry equipment with a volume of 1.2m (length) * 1.2m (width) * 0.7m (height). The basic shelf has 28 columns, 7 rows, 8 layers, a total of 1568 cargo spaces, and a total load of 2352t.

Warehouse stacker crane has strong applicability and wide application:

The warehouse stacker has strong applicability and can be used in production workshops, large retail beverage supermarkets, and warehouse storage of pharmaceutical companies. It suitable for various industries such as chemical industry, textile, auto parts, electronic products, supermarket warehouse, etc.

Systems:

1. Crane system: crane positioning system, anti-sway system, human-computer interaction HMI, crane remote control, wireless network settings, background server and crane body control, etc.

2. Warehouse management system: WCS management and WMS management, code scanning device, warehouse management system software, video monitoring system, wireless and wired network system, production docking MES interface.

3. The safety and warning system of the storage area: safety management of the working area of the crane, safety management of the ground sidewalk, safety management of the vehicle passage, various safety management indicators, alarms and safety barriers, etc.

.jpg)

Save power and improve efficiency:

1. The suspended stacker is mainly used in conjunction with the shelf, and is convenient to move during use, can save power, and save the occupied area of the stacker at the same time.

2. The automated 3D warehouse stacker brings great convenience to the logistics transportation industry and the large-scale warehousing industry. The stacker can not only improve the efficiency, but also reduce the damage rate of the goods. The stacker can protect the surface of the goods from damage to the greatest extent in the process of working.

Hoisting Mechanism | ||

Capacity | t | 3 |

Hoist Speed | m/min | 1.5~15 |

Working Duty | M5 | |

Max. Lift Height | m | 18 |

Stacker Forklift Speed | No Load m/min | 60 |

Full Load m/min | 30 | |

Power | Kw | 22+3 |

Power Supply | AC 3P 380V 50HZ | |

Traveling Mechanism | |||

Trolley | Crane | ||

Gauge | m | 2.5 | 20.2 |

Travel Speed | m/min | 3.8~38 | 5~50 |

Work Duty | M5 | M5 | |

Stroke | mm | 35 | 60 |

Max. Wheel Load | KN | 135 | |

Rail Track Specification | 60*40 | P43 | |

2*1.1 | 4*2.2 | ||

Power | Kw | 36 | |

https://www.weihuacraneglobal.com/case/One-Stop-Warehousing-Logistics-Solution.html

2021年1月17日星期日

Crane Cable Carrier / Weihua Crane

The crane cable carrier is used for the suspension and movement of the cables of the crane for mobile power supply, which has been widely used in various lifting machinery with the features of sturdy structure, mobile and flexible, Safe and reliable. This cable carrier can hold flat cable and round cable, running under C-rail or I-rail.

|

| crane cable carrier |

The cable carrier is device helping power supply of the crane trolley or hoist. It is composed of walking wheels, brackets, and pallets. The cable is hold on the pallet, and the traction frame is synchronized with the cable trolley to achieve the power supply for the trolley. Weihua cable carriers are divided into medium load type, heavy load type and light load type. Therefore, the wheels are Ф80, Ф63 and Ф50. And the load capacity is ≤50∽150kg. The pallet layers can be single Layer, double layer, and triple layer. The carrier at the head end is a tractor carrier, the end is a fixed cable rack, and the middle is the cable trolley.

Note:

1. After the fixed cable rack is installed, a baffle should be hung on the back;

2. Adjust the traction head so that the trolley does not touch the upper and lower edges of the traction hole during the entire travel;

3. The cable length is 1.2 times of the span of the crane and plus 8 meters.

4. Adjust the traction wire rope so that its length is less than the length of the same section of the cable. The traction wire rope is stressed during operation.

5. When the cable diameters are not equal, the cable clamps should be padded with soft rubber so that the outer diameters are basically the same in order to clamp the cables.

6. When laying cables, consider the balanced force on both sides of the cable support plate.

7. When the cable carrier has two or three layers, the requirements are the same.

8. The double washer on the carrier is an adjusting washer. When the guide rail is not suitable, put the washer on the inner side of the fixed plate to adjust the width of the gauge. It is made according to the guide rail specifications 100*68*4.5, 120*74 *5, 140*80*5, 160*88*6. Non-standard pulleys are processed according to drawings.

https://www.weihuacraneglobal.com/product/Crane-Cable-Carrier.html

Email: weihua@craneweihua.com

Graphite Electrode Crane

Graphite electrode crane is a multifunctional overhead crane which can realize the functions of automatic storage of graphite electrodes, graphite grouping, film winding, strings, automatic switching of single and double rows. The lifting part of the crane can realize the overall loading and unloading of single or double rows of multi-specification graphite electrodes. And lifting the furnace cover. It turns the complexity into simplicity. This product improves the product quality of graphite electrodes and truly realizes the efficient production of graphite electrodes.

|

| Graphite electrode crane |

Features:

1. Reasonable structure design; The graphite electrode string device adopts the main and auxiliary hydraulic propulsion device, mobile packing device, automatic drop device, damping roller device, etc., which are flexible and exquisite;

2. This product is a Weihua's original intelligent multi-functional graphite electrode crane, which can meet various specifications of electrode loading and unloading. At the same time, the spreader is equipped with furnace cover hooks that are suitable for furnace cover lifting and transportation to meet various needs of customers.

3. The complex spreader of this product is an innovative design, which not only satisfies the loading and unloading of single and double rows of graphite electrodes, but also satisfies the hoisting of the furnace cover. The design structure is cleverly used, and the safety device is set reasonably, which not only satisfies the large tonnage handling, but also satisfies the refined operation.

4. Weihua Technology Center has created an advanced graphite electrode handling crane for this field. This equipment will change the existing graphite electrode preparation method and is a brand-new creativity for the market.

https://www.weihuacraneglobal.com/product/Graphite-Electrode-Crane.html

Email: weihua@craneweihua.com

.jpg)