Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2021年1月7日星期四

Annealing Furnace for Metallurgy EOT Crane Trolley

2020年12月27日星期日

Crane Warning System

This crane warning system consists of a siren and a light. The siren and light work during crane working. This system can be used at project machines such as overhead crane, gantry crane, truck crane, all terrain crane, rubber type crane, STS crane, etc.

Features:

1. Audible and Visible;

2. Project plastic shell, durable and good performance;

3. Alarming sound is loudly and clear, simple use, working continuously, simple installation, adjustable sound volume.

Specification:

Rated Voltage: AC 220V (customized available)

Power Frequency: 50~60Hz

Sound Volume: A (customized available)

Sound Level: 106dB±5Db

Power: ≤10W

Alarming: Sound&Light

Light Type: LED (A233)

Working Temperature: -30~+70℃

Working Humidity: 10~95%

Protection: IP65

Siren Material: ABS; Light Material: PC

Color: red

https://www.weihuacraneglobal.com/product/Crane-Warning-System.html

Email: weihua@craneweihua.com

Crane Travel Switch

Travel switch is a travel limit and terminal protection for the crane traveling or hoisting. The travel switch can be a trolley travel switch. When the trolley approaches the limit position, the operation is stopped in one direction and can be operated in the reverse direction. The function of a crane travel switch is similar to the trolley travel switch.

.jpg)

.jpg)

|

| Travel switch |

2020年12月23日星期三

3D Animation of Crane Trolley - WeiHua Group

This video shows the 3D animation (Email: weihua@craneweihua.com) of crane trolley made by Weihua Group from China. You will see the features of Weihua Crane Trolley.

https://www.weihuacraneglobal.com/product/FEMDIN-Crane-Trolley--Crane-Trolley.html

Single Girder Overhead Crane with FEM DIN Standard

2020年12月20日星期日

Crane Conductor Rail System

Conductor rail system can be the single pole conductor bar system, seamless conductor rail system, and solid steel conductor rail system. As a leading crane manufacturer, Weihua provides all kinds of power supply systems for cranes.

|

| Conductor rail system |

1. Single-Pole Conductor Bar System

The single pole conductor bar materials are copper (200A-5000A) and aluminum (150A-3000A). The aluminum conductor bar is provided with a proven stainless steel contact surface (There is no need to add stainless steel strip in case the conductor used as busbar).

Any numbers of poles conductor bar can be installed vertically or horizontally, on straight or curved system. This single pole conductor bar system can be used outdoor with a protective cover which is antioxidant, UV resistant, impact resistant. For high temperature environment (-40 ~ 115℃), the protective cover is available with different sizes for different sized conductor bar. Besides, we supply the full set conductor system, including conductor bar, protective cover, jointing material, feed sets, end caps, hangers, expansion section, Current Collector, tow arm, support bracket, isolation section, etc.

Weihua also provides curved conductor bar with R≥1200mm. All conductor bars are approved by CCC, ISO9001 and CE.

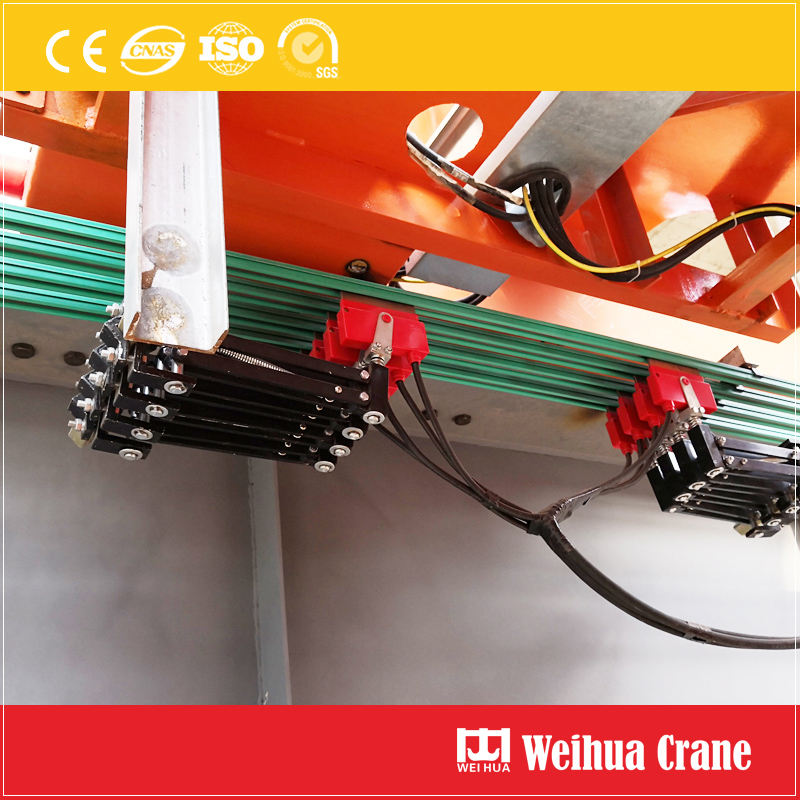

2. Seamless Conductor Rail System

The seamless conductor rail system is without any joints within length 1000m, which is available for 3P, 4P (50A, 80A, 100A, 120A, 140A) with load matching. Meanwhile 3P, 4P can be combined into the 6P or other level. Weihua provides complete seamless conductor rail system including components such as hanger clamp, bended joints, Current Collector, towing bracket, end tensioner/feeding, towing arm, carbon brush, support bracket, etc.

The seamless conductor rail system has the features of quick and easy installation, economical and practical, stable operation, fast speed, less noise, flexible power supply, etc.

4P Conductor Data:

Rating: 4P, 660V, 50A-120A

Conductor material: copper

Insulation cover/jacket: Rigid PVC within 75℃

Color: Orange (Eye-catching warning color)

3P Conductor Data:

Rating: 3P, 660V, 50A-120A

Conductor material: copper

Insulation cover/jacket: Rigid PVC within 75℃

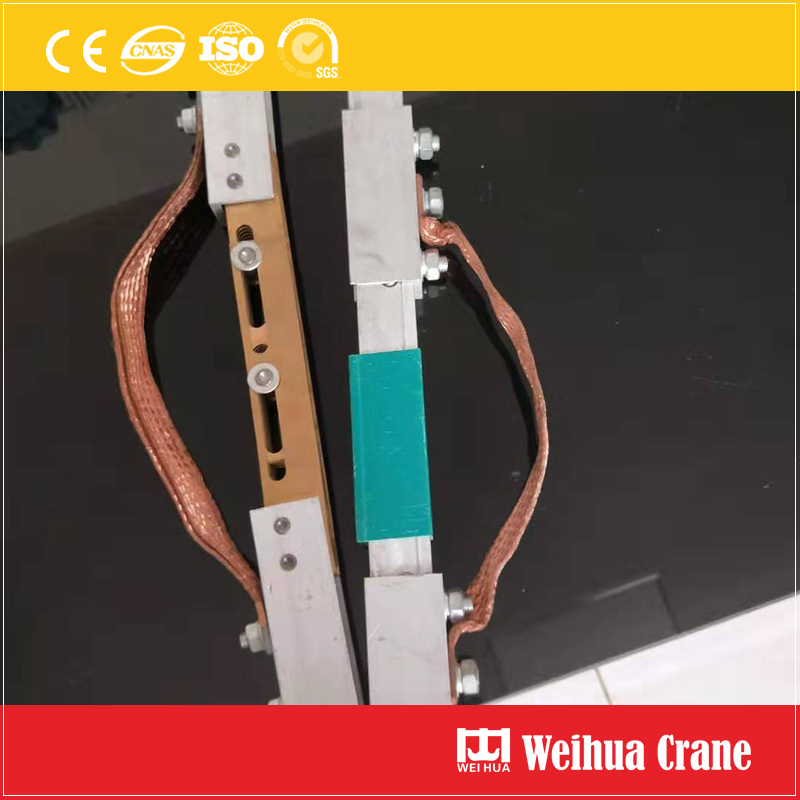

3. Solid Steel Conductor Rail System

The solid steel conductor rail system is an open style conductor system which is composed of a ladder type copper rod and a channel steel or a T shape copper row and a groove type aluminum. It is supported by high-strength special insulators to form a mobile sliding line that feeds lifting equipment.

The length of the conductor bar section is usually 6m and the insulation bracket installation spacing is generally 3m. This open solid conductor system is usually for large tonnage cranes. The power supply current is usually ≥800A, 1000A, 1600A, etc.

https://www.weihuacraneglobal.com/product/Conductor-Rail-System.html

Email: weihua@craneweihua.com

Weihua Production Capacity of Crane Trolleys +500t Make Great Progress

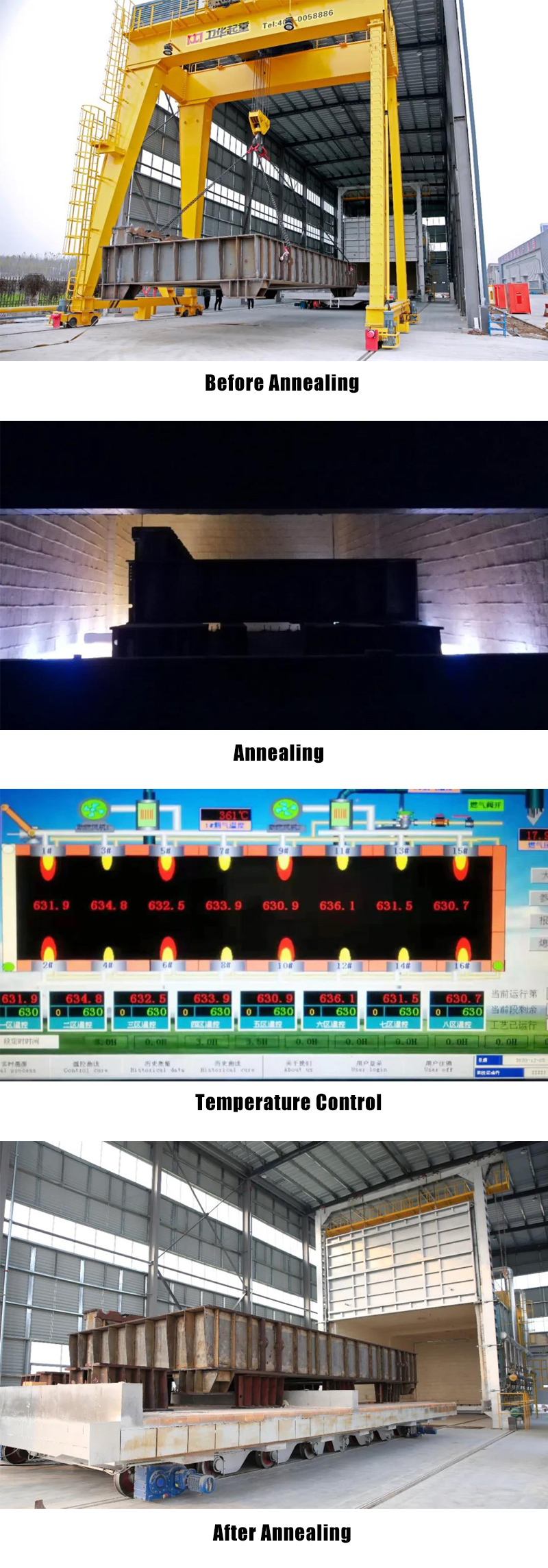

A few days ago, another heavy equipment was officially put into use at Weihua Crane Intelligent Industrial Park. A 16m×8m×6m heat treatment annealing furnace for heavy structural parts successfully realized the overall annealing of a 320t metallurgical trolley.

As the core process and processing technology of large metallurgical cranes, this large annealing furnace can meet the annealing treatment of various structural parts of large metallurgical cranes with capacity above 500t, and the equipment processing capacity has reached the leading level in the lifting industry.

1. Precise temperature control

The furnace temperature control accuracy is ±3℃, and the furnace temperature uniformity in the same zone is ±10℃. It adopts PLC control mode to automatically realize multiple heating processes.

2. Intelligent control

Three-dimensional heat storage, zoned furnace temperature control, nozzle size and layout can be set according to actual needs, so that the workpiece is evenly heated in the furnace.

According to the product structure, Weihua has formulated a special annealing process, which can improve or eliminate various structural defects and residual stresses in the welding process, improve the comprehensive mechanical properties of the workpiece, prevent fatigue deformation damage and weld joint cracking, and eliminate Potential safety hazards to ensure the dimensional stability of each organization.

Overall processing capacity of large metallurgical crane reducer:

1.Full-size processing capacity

With large-scale CNC floor boring and milling machines with 260mm and 200mm spindles, CNC gantry boring and milling machines and other equipment, as well as corresponding processing tools, it has a full-size, high-precision processing capability coverage for large metallurgical crane structural parts of 300t-500t and above.

2.Combined process & combined processing

The processing mode is transformed from single-piece processing to combined processing, and the whole process quality control mode is constructed.

3.Overall machining accuracy

It can realize the combined processing of large components and full-size large area, multi-directional boring, milling, and drilling. The linear positioning accuracy is 0.02mm, the axis parallel accuracy of each hole system is 0.015mm, and the flatness of the joint surface is good.

Weihua carried out many metallurgy crane projects for many big steel plants in China and overseas.

Email: weihua@craneweihua.com