Gantry Crane for Container Handling features: (Email: weihua@craneweihua.com) fatigue analysis and calculation for main girder, applicable for full-scale container spreader, cab with all round vision.

Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2020年11月18日星期三

3D Animation of Double Girder Overhead Crane

2020年11月15日星期日

Overhead Crane for Forging 250t / Weihua Crane

This 250t overhead crane for forging adopts the internationally advanced 3-beam 4-rail bridge structure, which is made by first-class processing equipment and advanced manufacturing processes. The scientific preparation of the manufacturing process and the use of advanced processing methods ensure the high quality of 250t forging crane.

|

| 250t overhead crane |

The overhead crane has been tested and meet the requirements of JB/T7688.1-2008. The product has been installed and commissioned on site and get recognition and praise from customers.

Features:

1. YD250/80t-33m-A6 (Main hook cap. : 250t, Vice hook cap. 80t, Span: 33m, Work duty: A6)

2. The crane is equipped with mechanical anti-shock function and mechanical anti-overload function, which is safe and reliable;

3. The crane is subject to 1.4 times static load and 1.2 times dynamic load test;

4. The crane is designed with 3-beam 4-rail, and both the main and auxiliary beams adopt a wide-flange off-rail box-shaped structure;

5. The crane is equipped with a special turning machine to lift and reverse the workpiece;

6. The key points of each part are calculated by finite element analysis technology;

7. The flexible design of the crane adopts bolts and articulated joints between the modules, which is convenient for installation and maintenance, improves the utilization rate of the plant, reduces energy consumption, and has strong adaptability;

8. The computer simulation and analysis technology are used to analyze and control the research and development results.

https://www.weihuacraneglobal.com/product/Overhead-Crane-for-Forging-250t.html

Email: weihua@craneweihua.com

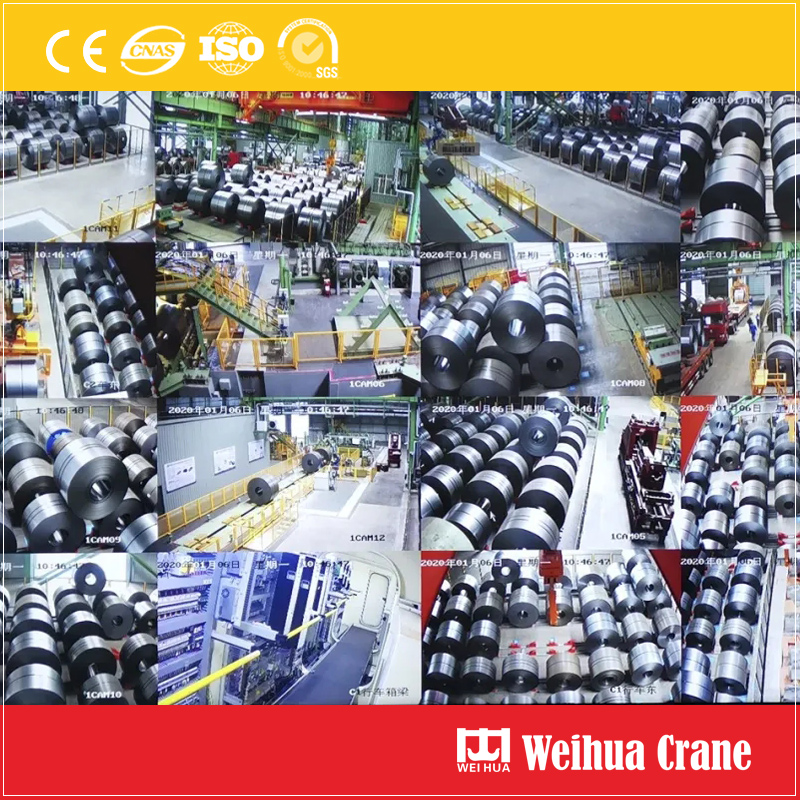

Intelligent Steel Coil Handling Crane / Weihua Crane

The intelligent steel coil handling crane capacity 35t is an integrated management system with information technology, network technology and sensor technology, combining of management, control and basic layers to the handling system to achieve intelligent and unmanned operation of the handling area.

|

| intelligent steel coil handling crane |

Features of Intelligent Steel Coil Handling Crane:

1. Span: 28.5 meters; Capacity: 35 tons

2. Warehouse management unattended

3. Truck scanning recognition

4. Intelligent identification and handling of steel coils

5. Visual inventory control

Independent R&D by Weihua

1. Visual Recognition Syste:

Scanning and Recognition of Vehicle Information and Steel Coil

Precise positioning

Realize intelligent unmanned automatic loading and unloading trucks and safety protection in the working area

2. Anti-sway System:

Automatic storage

The handling process is smooth and efficient

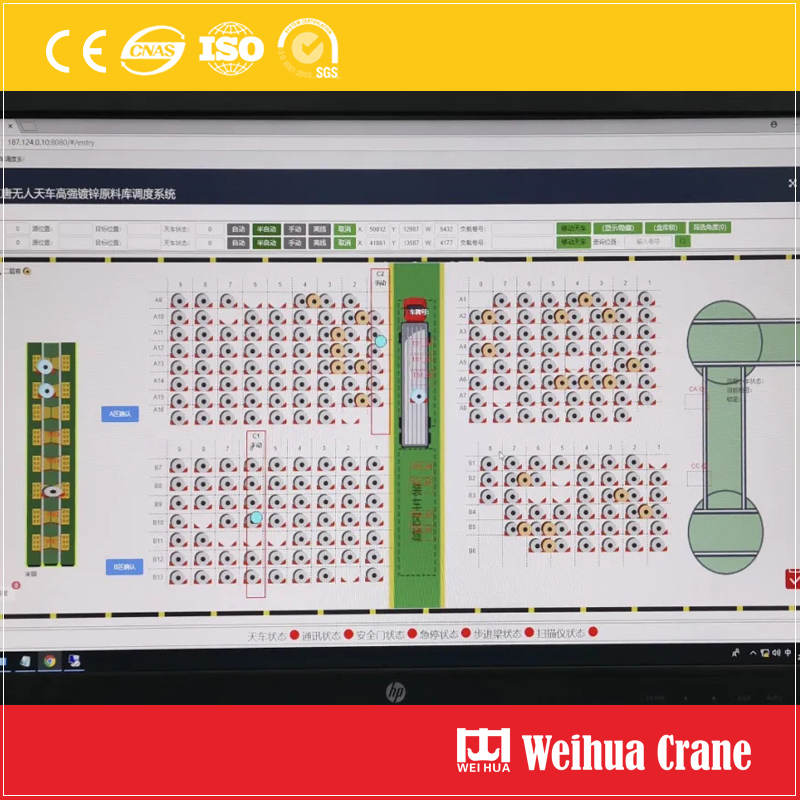

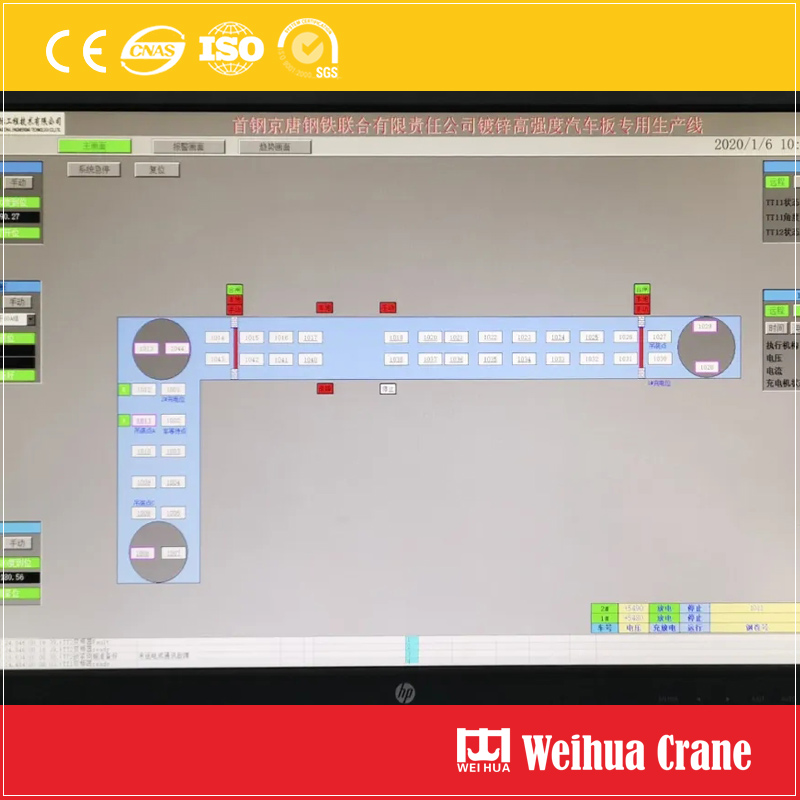

3. Data Cloud Platform Jointly Developed with Shougang:

Visual warehouse management scheduling system

+

Warehousing data management system

+

Intelligent production line scheduling system

+

Equipment condition monitoring system

Can be connected to all intelligent warehouse management systems

The intelligent steel coil handling crane and its data cloud platform system have been successfully applied to a number of modern intelligent factories such as Jingtang Iron and Steel Baotou Group, Sinosteel Machinery, etc. improving the production efficiency and intelligence degree.

https://www.weihuacraneglobal.com/product/Intelligent-Steel-Coil-Handling-Crane.html

Email: weihua@craneweihua.com

2020年11月9日星期一

Intelligent Quenching Crane / Weihua Crane

Intelligent Quenching Crane is mainly used for hoisting high-temperature profiles or bars and for carrying out the quenching process. After the high-temperature bars are released from the oven, they are transported by a flat car to the designated location. The heat-treatment crane runs in place and lifts the high-temperature bars for heat treatment in quenching pool, finally the bars were lifted and placed to the designated position, and wait for the instruction before proceeding to the next working cycle. The heat bar temperature is 1050℃ and the environment is very hot and humid. The biggest highlight of the entire process is Unmanned operation and Automatic operation.

|

| Intelligent Quenching Crane |

Advantages:

1. Weihua patented wire rope adjustment device:

The lifting mechanism adopts a single-drive double-drum structure to ensure the synchronization of the lifting of the double lifting points and the wire rope adjustment device can be used to quickly level the spreader.

2. Weihua independent patent anti-sway technology:

The whole machine is equipped with rigid guide column and horizontal guide wheel device with anti-sway and precise positioning function.

3. C-type hook special spreader:

Equipped with special spreader for quenching C-shaped hooks. Multiple C-shaped hooks are equipped with detachable pin assembly. The connection position is set on the side. Maintenance is convenient and the lifting space is effectively improved.

4. Intelligent Control System:

The control system is equipped with wireless remote control and ground pendant control. It uses famous-brand wireless communication equipment to realize the information interaction between the remote-control station and the driving. It has remote control and fully automatic control modes.

5. High-precision positioning:

The positioning system uses an absolute encoder and position detection switch to automatically correct to avoid accumulated errors and achieve high-precision positioning.

6. Safe and efficient:

The control system receives the commands sent by the host system to realize full-automatic operation. It has functions such as stable handling, light lifting, rapid quenching, and anti-collision.

https://www.weihuacraneglobal.com/product/Intelligent-Quenching-Crane.html

Email: weihua@craneweihua.com

Multifunctional Crane for Electrolytic Copper / Weihua Crane

The combined electrolytic copper multifunctional crane is an intelligent overhead crane. It is a special crane developed according to the production process requirements of electrolytic copper.

This crane is suitable for special working environments such as high humidity, corrosion and metal dust. The high-standard design, manufacturing, and assembly ensure the safe and reliable operation of each mechanism; its highly intelligent automatic control system and spreader are of unparalleled advantage.

1. Strengthen Design, Improving Accuracy

· Strengthen design of the main beam, greatly improving the mechanical performance and load-bearing capacity.

· The main lifting mechanism realizes synchronous lifting and is equipped with anti-chaotic rope and anti-wear devices, which can be widely used in multi-lifting point lifting equipment.

· Automatic positioning to improve the positioning accuracy of crane and trolley and the positioning accuracy of spreaders.

2. Highly Intelligent, Safe Operation

· The automation application program can carry out remote network control of the whole crane, realize the operation monitoring of the whole machine and provide fault indications and solutions, and the product operation realizes a high degree of intelligence.

· It has emergency manual control system, which will continue to operate the crane to complete the process safely and stably in case of communication errors.

· Electrical insulation ensures the safe use and maintenance of cranes and spreaders on high-current electrolyzers.

3. Various Controls, Automatic Operation

· There are three control modes: cab operation, remote control operation, and ground station operation, ensuring that the lifting status can be controlled at any time, and the lifting operation can be carried out easily, and it realizes the automatic flow operation of the workshop.

https://www.weihuacraneglobal.com/product/Multifunctional-Crane-for-Electrolytic-Copper.html

Email: weihua@craneweihua.com

2020年11月5日星期四

WH Light Flexible Combined Crane

Features of Flexible light crane system: (Email: weihua@craneweihua.com) 1. Flexible free combination orbit; 2. Modular system design; 3. Adopt standard chain hoist.

https://www.weihuabridgecrane.com/product/WH-Flexible-Suspension-Crane-System.html