Rated Capacity / SWL: 3 ton, 5 ton, 10 ton, 16 ton, 20 ton, 32 ton, 50 ton, 80 ton

NR Electric Hoist Types/Models:

1. NRL (Low-Headroom Monorail Hoist)

2. NRS (Standard-Headroom Monorail Hoist)

3. NRT (Double-Rail Trolley or Crab)

4. NRF (Foot-Mounted Hoist)

Model NRL (Low-Headroom Monorail Hoist) Capacity: 3 ton, 5 ton, 10t

Model NRS (Standard-Headroom Monorail Hoist) Capacity: 3 ~ 80 ton

Model NRT (Double-Rail Trolley or Crab)

Model NRF (Foot-Mounted Hoist)

Motor:

- NMD Double Speed Motor

- NMF Frequency Conversion Motor

- Lifting motor power: 3.2 Kw, 4.9 Kw, 9.8 Kw, 16 Kw, 18.5 Kw

- Traveling motor power: 0.44 Kw, 0.64 Kw, 0.96 Kw, 1.3 Kw, 1.9 Kw

Reducer:

- NGL Lifting Reducer

- NGT Traveling Reducer

- Lifting Reducer: NGL01, NGL02, NGL03, NGL04

- Traveling Reducer: NGL02, NGL03, NGL04, NGL05

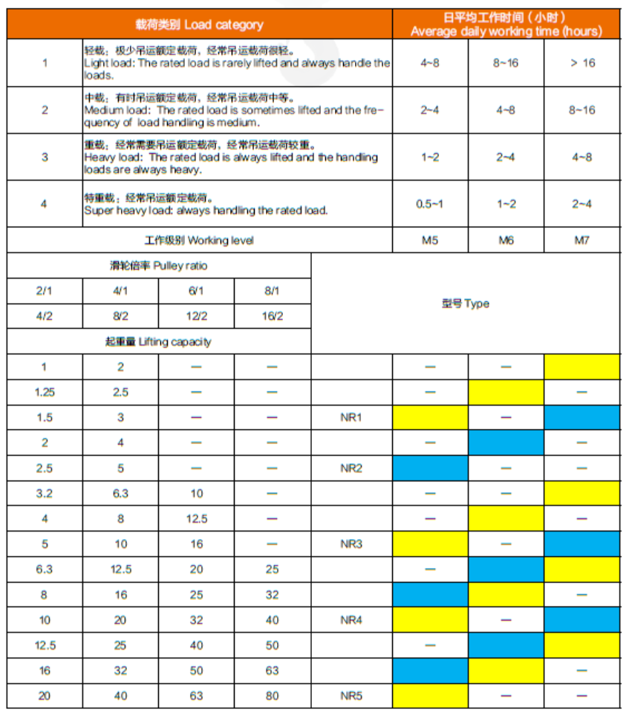

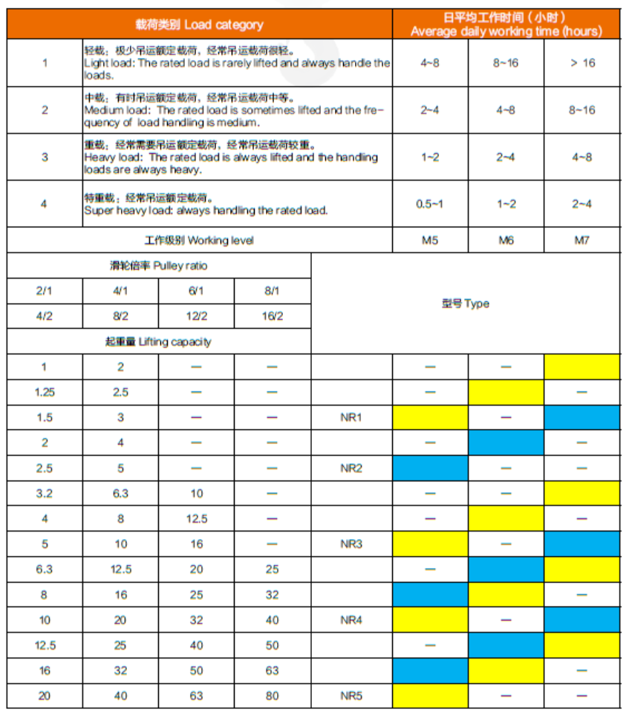

Main parameters:

- Standard: FEM

- Working Duty: M5 ~ M7

- Lifting Speed:

3t, 5t, 10t: 5/0.8 m/min (4/1);

16t: 3.3/0.5 m/min (6/1); 5/0.8 m/min (4/1);

20t: 4/0.67 m/min (4/1); 5/0.8 m/min (4/1);

32t: 3/0.5 m/min (6/1); 0.8~5 m/min (8/2);

50t: 0.5~3.3 m/min (12/2);

80t: 0.4~2.5 m/min (16/2);

- Traveling Speed: 2.0 ~ 20m/min

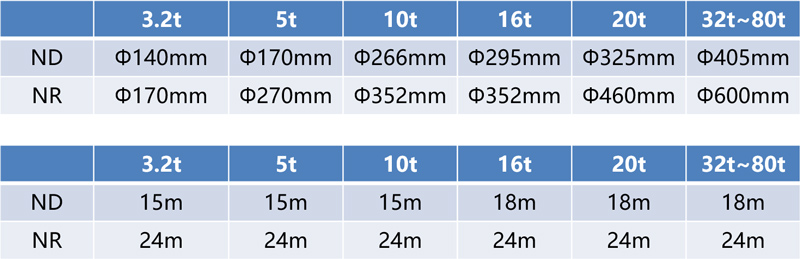

- Lifting Height: 6m ~ 24m

NR Electric Hoist Features:

1. Without reverse rollers/wheels;

2. Bilateral drive, the reducer directly drives the wheels;

3. The hoisting mechanism is more convenient and quick to connect, also available for the trolley structure;

4. Capacity 3t, 5t hoist lifting mechanism is with fully closed structure, the other capacity hoist is with open gear drive;

5. Dual drive for capacity 32t~80t variable frequency hoisting mechanism;

6. Capacity 3t~16t lifting mechanism is with C-type structure, while capacity 20t~80t lifting mechanism is with Z-shaped structure.

Lifting Gear Motor Features:

1. Lifting motor is a gear motor, the front cover of the motor is connected with the reducer, and motor shaft head drives the gears;

2. The motor case is stretched aluminum (6063), and the reducer case cover is cast aluminum alloy (ADC12);

3. Motor performance: S3-40%, Class F IP54, 2/12 pole dual speed, 4 pole frequency conversion;

4. Reducer: Hard tooth surface, 20CrMnTiH;

5. Brake: Electromagnetic disc brake.

Lifting Gear Motor

Traveling Gear Motor Features:

1. Coaxial structure;

2. Traveling motor is a gear motor, the front cover of the motor is connected with the reducer, and motor shaft head drives the gears;

3. The reducer is an output spline shaft structure with flanged connection;

4. The motor case is made from stretched aluminum (6063), reducer case covers are made from cast aluminum alloy (ADC12) or cast iron (HT250);

5. Trolley and hoist share the same running;

6. Motor performance: S3-40%, Class F IP54, 4 pole frequency conversion;

7. Reducer: Hard tooth surface, 20CrMnTiH;

8. Brake: Electromagnetic disc brake.

Traveling Gear Motor

Components Features:

1. Reel/Drum: Finished steel pipe (with ring gear for 10t above capacity hoists);

2. Wire Rope: 1960~2160 grade wire rope;

3. Hook Block: New hook set with beautiful appearance;

4. Fixed Pulley: MC nylon pulley, pulley shaft is overload sensor;

5. Rope Guide: Nylon rope guide;

6. Rope wedge: Standard wedge;

7. Wheel Group: Internal spline structure (without the torque support of the reducer), ductile iron.

Structure Features:

1. The hoist frame consists of plates and rods;

2. Assembly after painting, high-strength bolt connection;

3. Flange plate bending structure on both sides of the reel;

4. Small structure rotation limit, flange connection;

5. Lifting and hoist frame with pin connection.

Low-Headroom Monorail Hoist Exploded View

6. Lifting structures is the same with the trolley type;

7. Use a large number of rectangular tube structures;

8. The driving wheel is with an internal spline structure, and the driven wheel is similar to a monorail wheel structure.

Double-rail Crab Exploded View

Double Gider Hoist Installation

Electric Box with Danger and Warning Signs

NR Electric Hoist Advantages:

1. Modular and universal:

6 kinds of punching and base

10 motor power

4 lifting gear reducers

4 kinds of running reducers

7 wheel sets

2. Core components are produced independently, with controllable core technologies:

Guaranteed Quality

Guaranteed Delivery

Non-standard design

Gear Motor Production Line

3. Full range of NR electric hoist adopts large diameter reels with less left and right limit;

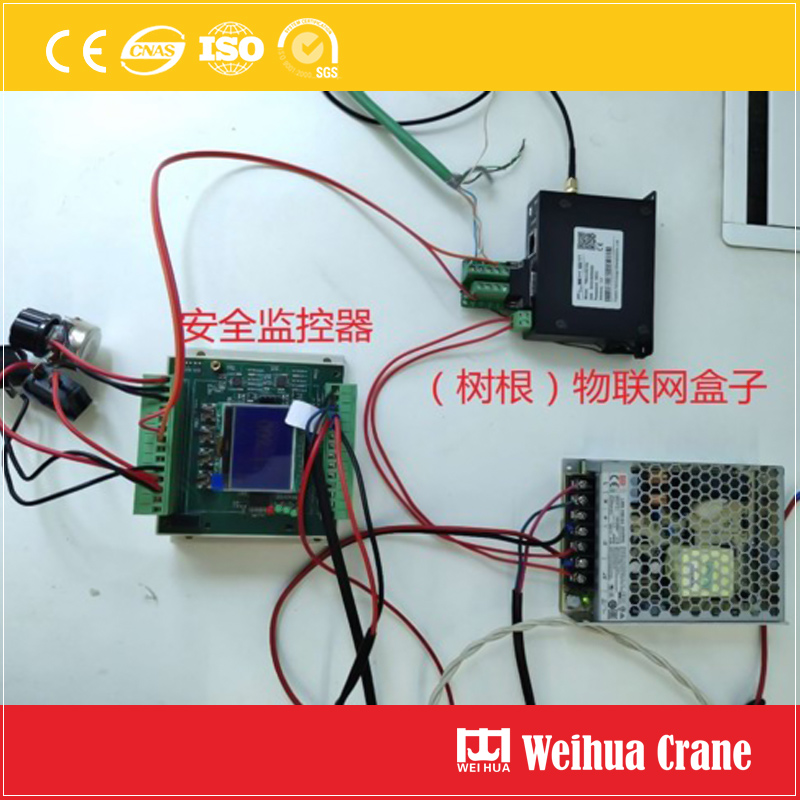

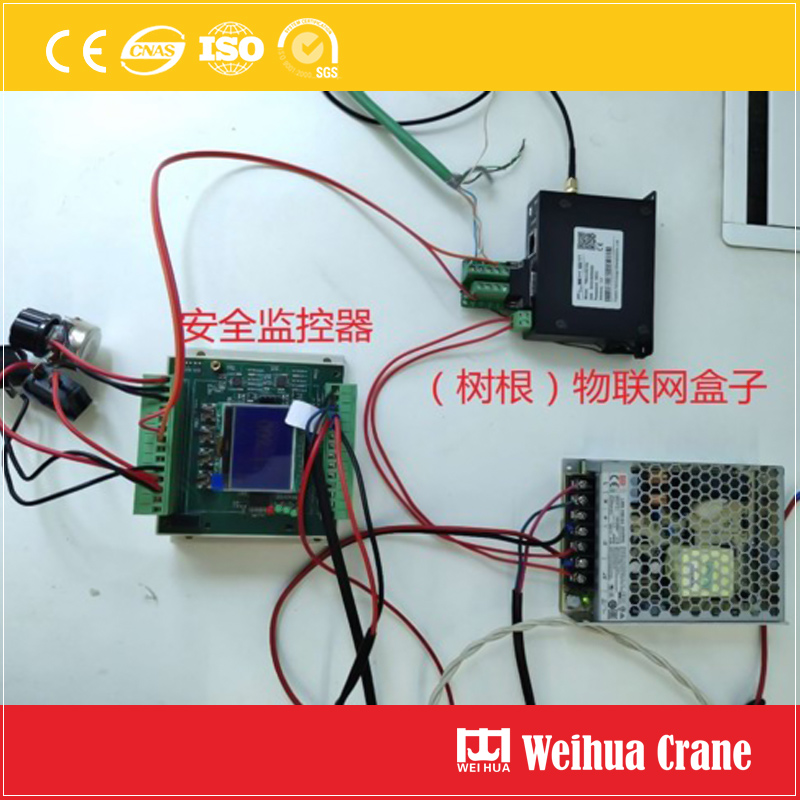

4. A new safety monitoring system with functions of overload protection, Information statistics and inquiry, fault inquiry, collaborative work of 2 hoists, etc.

5. Internet of Things (IOT) cloud connection: Through the security monitor and the (tree root) IoT module communication, the cloud platform storage and remote monitoring of the NR hoist data is realized.

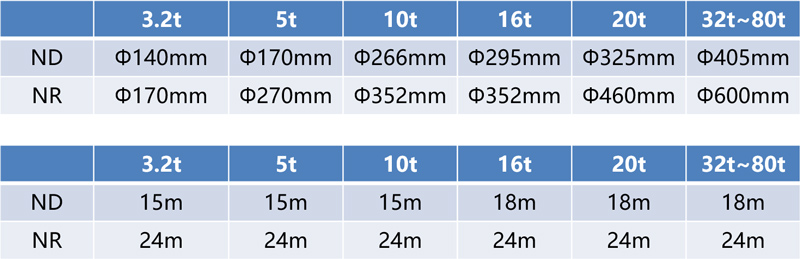

Reel/Drum Diameter

Safety Monitoring System

Tree Root IOT Box

https://www.weihuacraneglobal.com/product/NR-Electric-Hoist.html

Email: weihua@craneweihua.com

.jpg)

.jpg)

.jpg)