Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2020年7月28日星期二

WEIHUA GROUP - 2016

Weihua Group, (Email: weihua@craneweihua.com) Chinese top manufacturer and supplier of overhead cranes, gantry cranes, port cranes and hoists. https://www.craneweihuaglobal.com

2020年7月27日星期一

Bridge-type Grab Ship Unloader / Weihua Group

The bridge-type grab ship unloader is a kind of important cutting-edge unloading equipment in the wharf. Considering that the foregoing ship unloader can play an important role for the system's working efficiency, it has been widely applied to all kinds of ports. As a result, the bridge-type grab ship unloader has developed into the main ship unloading machinery in the bulk importing area in the wharf by right of its maturity, reliability, strong adaptability of ship type and commodity, high production efficiency, high automation degree, low failure rate, convenient maintenance and other advantages.

|

| bridge-type grab ship unloader |

It is worth mentioning that our company's bridge-type grab ship unloader has also developed into the most commonly used ship unloader in the bulk port. It can be suitable for the 3,000t-250,000t degree bulk ships.

Performance Features:

1. It has the optimal flexible schedule and wide adaptability, moreover, which can adapt to the bulk commodities which have different densities and particles after replacing its hand grabs.

2. Due to the matured product, simple structure and strong reliability, it can be widely used in the bulk unloading from ships in the seaport.

3. Considering that its reclaiming grab bucket has simple structure, it is simple to repairing and maintaining the ship unloader due to the small workload.

4. It has the special superiority when the corrosive bulk commodities are unloaded.

5. It has strong adaptability for the different particle sizes of bulk materials, such as, the materials with more than 300-800mm particle size can be grabbed.

6. It has good adaptability for the hatchways of the bulk ships, meanwhile, which will not be affected by the tidal level.

2. Due to the matured product, simple structure and strong reliability, it can be widely used in the bulk unloading from ships in the seaport.

3. Considering that its reclaiming grab bucket has simple structure, it is simple to repairing and maintaining the ship unloader due to the small workload.

4. It has the special superiority when the corrosive bulk commodities are unloaded.

5. It has strong adaptability for the different particle sizes of bulk materials, such as, the materials with more than 300-800mm particle size can be grabbed.

6. It has good adaptability for the hatchways of the bulk ships, meanwhile, which will not be affected by the tidal level.

Email: weihua@craneweihua.com

Weihua Won a Bid of Shipyard Project in Russia

After 10 rounds of fierce bidding, Weihua Russia office successfully won a bid of shipyard project in Russia and signed the contract with the absolute advantage of the new-type crane solution. At present, 17 new-type double girder bridge cranes are in the product drawing design stage.

Since its launch in the Russian market, Weihua Crame has won many favors with its high-quality products. Weihua carried out many projects such as Bangladesh nuclear power project, Lupur Atomic Energy Group project, Mali Pulp and Paper Mill project, Russian Atomic Research Institute project, etc. All the projects got unanimous praise from Russian customers.

Click to know more project case https://www.weihuacraneglobal.com/case/

Email: weihua@craneweihua.com

2020年7月21日星期二

WEIHUA CRANE AMÉRICA-líder mundial en fabricación de grúas

WEIHUA CRANE AMÉRICA es un fabricante (Email: weihua@craneweihua.com) y proveedor líder para grúa Viajera,grúa Pórtico,grúa Portuaria y polipasto en el mundo. https://www.weihuacraneglobal.com

Grúa liviana y flexible

La Grúa liviana y flexible se utiliza para la línea (Email: weihua@craneweihua.com) de transportador de producción moderna,sus características ventajas son la combinación de orbitales libres,el sistema de diseño modular, el polipasto de cadena estándar,con posicionamiento preciso, rápido y fiable.

https://www.weihuacraneglobal.com/product/Flexible-Light-Combined-Crane.html

Email: weihua@craneweihua.com

2020年7月19日星期日

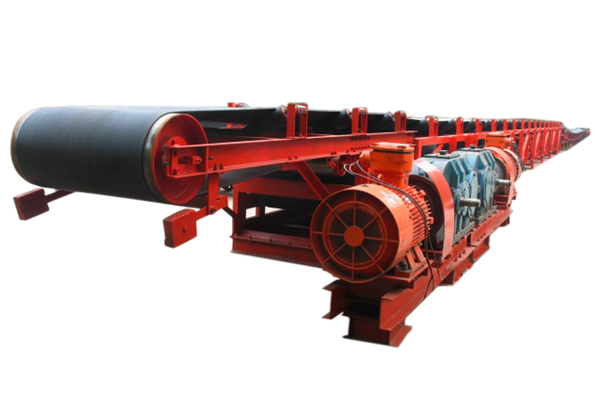

Extension-type Belt Conveyor / Weihua Group

The extension-type belt conveyor is mainly used for the crossheading transportation on the comprehensive mechanized mining surface, meanwhile, which is still suitable for the crossheading transportation and roadway construction transportation on the general mining surface. When the above-mentioned conveyor is used for the crossheading transportation, the scraper machine shall be provided on its afterbody to connect with the transport machine on the working surface; During the roadway construction transportation, the tape transferring machine will be provided to connect with the roadheader on its afterbody.

|

| extension-type belt conveyor |

Structure Principle:

1. Machine head 2. Tape accumulator 3. Movable roller rack 4. Redirection cylinder rack 5. Traction winch 6. Steel wire rope 7. Traction steel rope 8. Guide cylinder rack 9. Tail 10. Redirection cylinder

Performance Features:

1. The tape accumulator can prolong or shorten the machine to effectively enhance the crossheading transportation capacity and speed up the backstopping and tunneling progress.

2. The movable machine applies the fast detachable bracket which has no bolt for connection, therefore, which has the following advantages, such as, simple structure, convenient assembly and disassembly, low labor intensity and short operation period.

3. The tape tensioning device which is installed on the machine shall be tensioned in the large stroke by the electric winch.

Email: weihua@craneweihua.com

Weihua Won the Bid for 2,000t Gantry Crane Project

Weihua won a bid from China Guangdong Nuclear Power Lufeng Marine Engineering Base. It is a lift capacity 2,000t rail-mounted gantry crane project at hydraulic engineering base.

This gantry crane mainly serves for the representative anti-sway control system and synchronous lifting of the wind power equipment at the production base. It is particularly important for the turning, assembly, closing, loading and unloading operations of the wind power tower. It carries out the transportation, loading and unloading of large-scale offshore wind power equipment cabin, fan hub, wind power tower, steel pipe piles and blades.

1. Large lifting weight and high lifting height:

The lifting weight is up to 2,000t, the total lifting height is up to 90m, and the span is up to 62m, which solves the lifting problem of important marine equipment.

2. Nuclear industry standard, the world's highest safety level:

The gantry is with a double-trolley structure and each trolley is equipped with two sets of lifting mechanisms, which can ensure that the lifting heavy objects can be safely lowered to the ground under extreme conditions. The manufacturing process uses the Nuclear Industry Quality Management System to monitor the entire process to ensure that the product quality is completely controlled.

3. Smooth start-up and zero-speed braking:

It can realize the zero-speed braking of each mechanism, reduce the load caused by the impact to zero, ensure the stability of the operating mechanism and the lifting mechanism, and meet the requirements of equipment installation accuracy.

4. Four-point simultaneous lifting and simultaneous operation of all points:

It uses four lifting points synchronous lifting technology, by measuring the location of each lifting point, to ensure that each lifting point runs synchronously.

5. Real-time monitoring of working conditions, predictive maintenance of equipment:

It is equipped with crane management safety monitoring 5G data information management system, which can realize the functions of overall data statistics, real-time monitoring of product working conditions, historical data query, rapid repair of product failures, and predictive maintenance of equipment.

Email: weihua@craneweihua.com

订阅:

评论 (Atom)