As a kind of environment-friendly continuous transport equipment, the circular tube belt conveyor is mainly used for transporting coal, colliery coal, coke, blending materials, sintered ore, mineral powder, petroleum coke, limestone, sand-gravel aggregate, acetylene sludge, humidifying dust, chemical fertilizer, salt, waste paper, phosphorus gypsum, sulfur-iron slag and all kinds of bulk materials. The circular tube belt conveyor has the same working principle with the ordinary belt conveyor; namely, make use of friction to move the conveyor belt and its materials. The most of components can be commonly used with the ordinary belt conveyor, however, the difference is that the conveyor belt shall be rolled up in the circular tube shape.

Performance Features:

1. It can seal and transport the bulk materials.

2. It can arrange the transport routines in the space warp way.

3. It can enhance the transport inclination angle.

4. There is no off-tracking phenomenon.

5. It can transport materials in two directions.

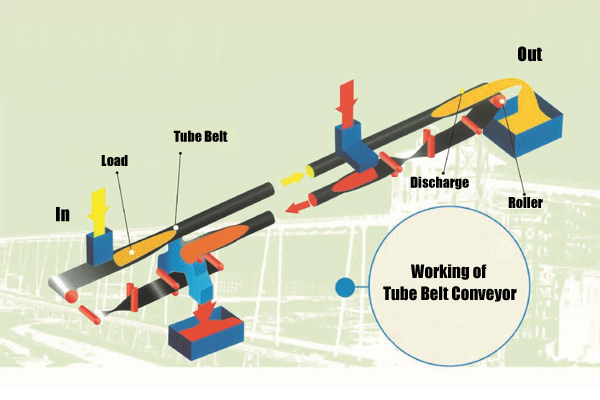

Principle and Structure of Circular Tube Belt Conveyor:

1. Common discharge port

2. Charging port

3. Transition section of materials receiving

4. Special tubulous tape

5. Transition section of materials unloading

6. Transmission Roller

|

| circular tube belt conveyor |

When the conveyor belt has received the materials from the transition section on its tail, the conveyor belt will be rolled up in the circular tube shape gradually, then, the circular tube tape will be applied to transport the materials in the sealed way, then, the conveyor belt will be unfolded gradually when the materials are transported to the head transition section until the materials are discharged. (As the figure shows)

.jpg)

.jpg)

.jpg)

.jpg)