Overhead Cranes, Gantry Cranes, Container Cranes, Port Cranes, Electric Hoists, Crane Accessories... Homepage: https://www.weihuacraneglobal.com

我的博客列表

2020年5月12日星期二

Rubber Tyred Gantry Crane with Electromagnetic Beam for Steel Pipe Handling

This is a 3D animation video (Email: weihua@craneweihua.com) shows the rubber tyred gantry crane (RTG) with electromagnetic hanging beam for steel pipe handling. The tyres can carry out in-place rotation, 45 degree rotation, 90 degree rotation, etc.

http://www.weihuacraneglobal.com/product/Rubber-Tire-Gantry-Crane-for-Steel-Pipe-Handling.html

Email: weihua@craneweihua.com

Container Rail Mounted Gantry Crane / Container Crane / RMG / Weihua Crane

Features of Weihua Rail Mounted Gantry Crane for Container Handling:

1. U-type frame, double cantilever with rod, strong, light weight.

2. Large gantry span and width, continent container loading and unloading

3. 360° rotating spreader with excellent adaptability and efficiency.

4. Long Traveling Mechanism Assembly

5. Frame/Gantry Assembly

6. Trolley Assembly

7. Electrical Control System

8. All digital frequency conversion and PCL control technology

9. High Precision Sensor Data Acquisition Technology

10. Industrial computer data analysis and processing system

Rail-type container gantry crane is mainly consists of the steel structure, lifting mechanism, micro-transfer mechanism, spreader anti-sway system, crane travelling mechanism, container spreaders, electrical equipment, and other necessary auxiliary equipments.

The container rail mounted gantry crane adopts frequency conversion, PLC control system and CMMS fault detection system. Main standard reference: GB/T19683-2005, JT/T566-2004, and ISO standard of International Standardization Organization, European FEM, Japan JIS standard.

Features of Container Rail-Mounted Gantry Crane:

1. This crane can be used in inland terminals, container yard, rail freight station, coastal freight yard and frontier wharf.

2. Adopt dedicated container spreaders which can handle 20 feet, 40 feet and 45 feet containers.

3. Electrical drive system is full digital AC frequency conversion, PLC control speeding, CMS intelligent monitoring and management system, the running state real-time monitoring equipment.

4. The upper trolley can rotate 270 degree for easy load and unload.

5. Three-in-one reducer is adopted for long travel and cross travel, easy maintenance.

6. Safety protection: Anti-breaking shaft, wind warning, anti-tipping, etc.

Depending on the constitution of main girder, outriggers and anti-sway device, container rail mounted gantry crane can be divided into different types.

1. Double cantilever gantry crane has big room between its outriggers for containers to pass through. Usually opening widely at upper parts to form a shape of U and combining with the girder forming a shape of N.

2. Non-cantilever crane has a simple structure because of containers do not need to pass through the room between its outriggers.

Compared with ship-to-shore gantry crane, the trolley of Rail Mounted Gantry Crane travels at a lower speed and usually equipped without anti-sway stabilizer, while it will be equipped with anti-sway device if users need it for reducing operation stress and improving production efficiency. For rope type lifting mechanism, increasing the rope damp is a usual way to accomplish stabilization. And for rigid type lifting mechanism, its own rigid components are available to accomplish stabilization.

http://www.weihuacraneglobal.com/product/Container-Rail-Mounted-Gantry-Crane--Rail-Mounted-Gantry-Crane.html

Email: weihua@craneweihua.com

Weihua Crane Assist Launching of Carrier Rocket Long March 5B

On May 5, the Long March 5B carrier rocket developed for China's manned space station project made its first successful flight in Wenchang, Hainan. In this launch mission, Weihua crane provided the rocket with high-precision hoisting and transshipment protection with advanced technology.

In Hainan Wenchang Satellite Launch Base, Weihua Group's over cranes undertaken the key link of rocket transfer and hoisting, and completed the handling, turning, and testing of rockets in the plant with high precision. Although the cranes are big and sturdy, their lifting accuracy reaches an astonishing 2 mm. The secret is that they have a sensitive Brain that can pass through the needle thread-equipped with anti-sway technology independently developed by Weihua, which can reduce the amplitude of swing by 95% and improve the stability and accuracy of the rocket during lifting.

Weihua lifting equipment has been serving aerospace engineering for a long time. It is the contractor of lifting equipment for 4 China satellite launch bases in Jiuquan, Taiyuan, Xichang, and Wenchang, helping the detector, the Long March rockets, the Mozi, and the Shijian 13 satellite successfully flew to the sky. In the journey accompanying the development of China's aerospace industry, Weihua Crane has accomplished all tasks excellently with the advanced lifting technology, excellent quality assurance, responsible professional attitude and perfect after-sales service, and has been unanimously agreed Praise and have won major contribution awards many times.

http://www.weihuacraneglobal.com/news/Weihua-Crane-Assist-Launching-of-Carrier-Rocket-Long-March-5B.html

Email: weihua@craneweihua.com

2020年5月6日星期三

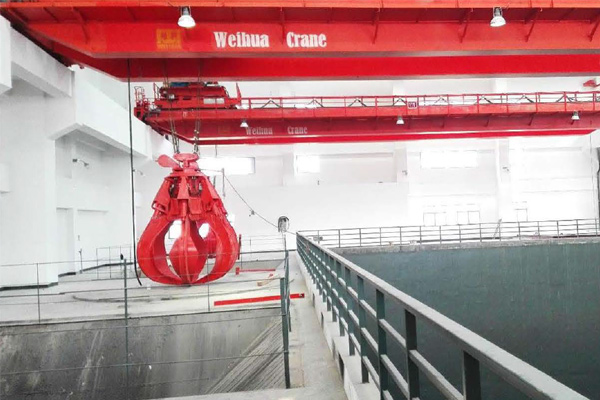

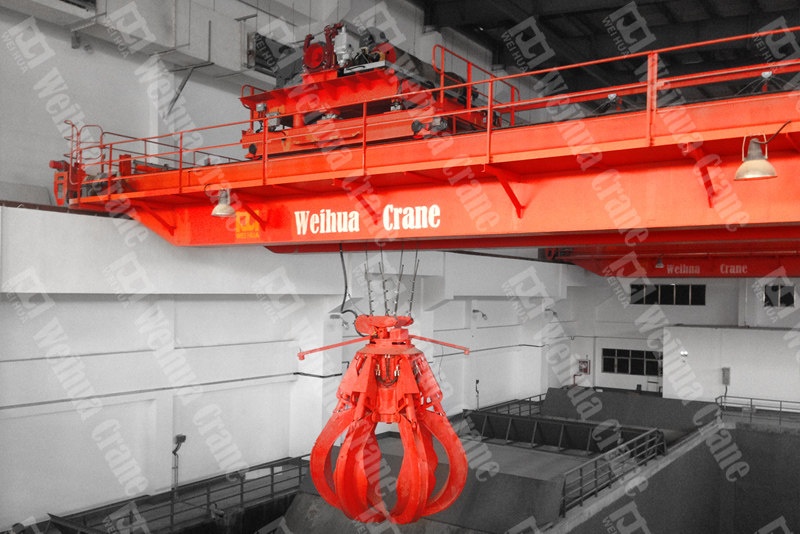

Double Girder Overhead Crane with Grab / Weihua Crane

Double girder overhead crane with grab consists of girders, crane traveling mechanism, trolley, electric system and grab. Double girder overhead crane with grab is widely used in power stations, warehouses, workshops and ports to grab or lift bulk materials. The lifting capacity includes the weight of grab and the grab opening direction is parallel or vertical to the main girders.

Mechanisms of Double Girder Overhead Crane With Grab:

1. Double girders, box-type shaped by wielding, and the camber degree meets China standard;

2. Adopt high quality carbon steel Q235B and Q345B;

3. Efficient brake, long service life;

Electric System:

1. Safety slide contact line or angle slide contact line;

2. Trolley power supply through flat cable;

3. Traveling smoothly and beautiful exterior;

Protection Devices:

1. Rain covers for lifting mechanism, motor box and drive system outdoors;

2. Anti-collision device, sound and light alarm device;

Control System:

1. Handle control;

2. Cab control can be customized according users' needs with intermediate working level;

3. The cab can be open or close style installed left or right;

4. Entrance of cab: side entrance, end entrance and top entrance.

.jpg)

http://www.weihuacraneglobal.com/product/Double-Girder-Overhead-Crane-with-Grab--Overhead-Crane-with-Grab.html

Email: weihua@craneweihua.com

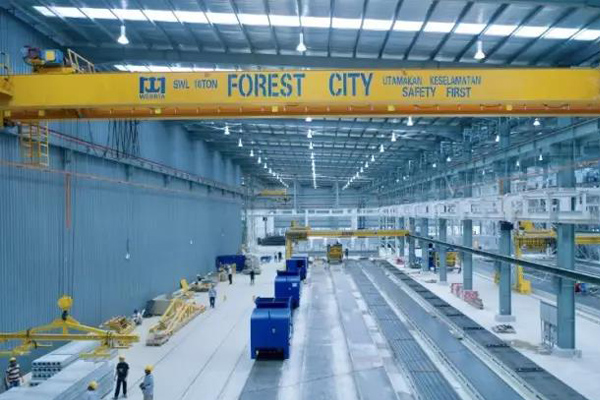

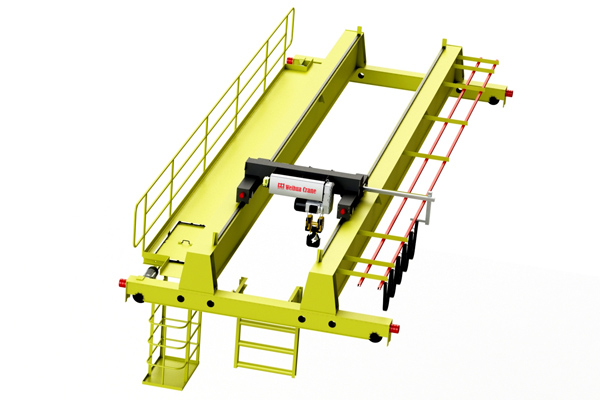

FEM/DIN Double Girder Overhead Crane / Weihua Crane

FEM/DIN standard double girder overhead crane is designed and manufactured with European standard. The lifting capacity of this FEM/DIN double standard overhead crane can be up to 800t. The trolley is installed between two main girders. Thus it increases the traveling scope of spreader. This crane is with reliable performance, flexible application range, easy to operate and convenient to maintain.

Lightweight and Modular Design:

1. Overall height is 20%~25% lower than traditional cranes;

2. Self-weight is lighter by 20%~30%;

3. Max wheel load reduces 15%~20%;

4. Smaller limiting size increases working scope;

5. Light structure reduces the cost of workshops;

6. Every component designed to be a standard series and interchangeable;

7. Modularization design is easy for transporting;

8. Standard modular design makes good quality and fast delivery.

Advanced Manufacturing Technology:

1. Sandblast pretreatment on steel plates and the surface quality reaches Sa2.5;

2. CNC cutting machine cuts webs plate to insure the curved surface is smooth and accurate;

3. Seams are soldered by automatic arc welding and detected by ultrasonic and X-ray ;

4. The structure of girder and trolley is manufactured by floor-type boring lathe to insure flatness.

Safety:

1. Safety supervision system is with an overload limiter and shows the load value on screen to warn operator to avoid overload;

2. Before start up, the whole system will carry out self-checking includes: power supply voltage, default phase, validity of the safe protection device and the zero button;

.jpg)

High Reliability:

1. Use imported motor with insulation grade of F and protection degree of IP54. With overheat alarm. The motor is shielded by aluminum alloy stretching cover with good heat dissipation performance;

2. Imported reducer from Germany. hardened gears with good bearing capacity, excellent seal without penetration of grease;

3. Main electric components imported from international brands such as: Siemens, Schneider and ABB etc. with protection degree not lower than IP54;

4. Wheels are forged by 65mn alloy steel with features of wear-proof, anti-fatigue and long service life.

5. Low energy consumption and maintenance free;

6. Whole crane energy saving about 30%;

7. All-in-one transmission mechanism making it work more efficient;

8. Variable frequency control whose high and low rotating speed ratio is 1:10 and work efficiency increases more than 20%;

9. Less and easy maintenance reduces the cost of maintenance;

10. Manufactured by advanced technology and constituted by high quality imported components greatly reducing malfunction and cost;

Intelligent:

1. Electric anti-sway tech realize accurate positioning;

2. Advanced electric control tech turn it into a crane robot with semi-automatic control and full-automatic control;

.jpg)

.jpg)

http://www.weihuacraneglobal.com/product/FEMDIN-Double-Girder-Overhead-Crane.html

Email: weihua@craneweihua.com

2020年4月27日星期一

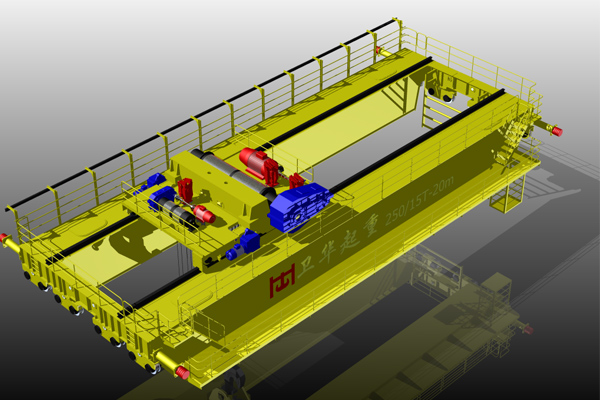

200t+32t Overhead Crane Delivery

Weihua made several overhead cranes for CSSC. The images show the delivery of No.2 and No.4 overhead crane. The No.2 overhead crane is a 200/32t capacity overhead crane with span 41.3m and double trolleys. And No. 1 overhead crane have been installed and and debugged.

Weihua is leading crane manufacturer in China providing overhead crane, gantry crane, project crane, jib crane, container crane, metallurgy crane, etc.

http://www.weihuacraneglobal.com/news/200t-32t-Overhead-Crane-Delivery.html

Email: weihua@craneweihua.com

Weihua is leading crane manufacturer in China providing overhead crane, gantry crane, project crane, jib crane, container crane, metallurgy crane, etc.

http://www.weihuacraneglobal.com/news/200t-32t-Overhead-Crane-Delivery.html

Email: weihua@craneweihua.com

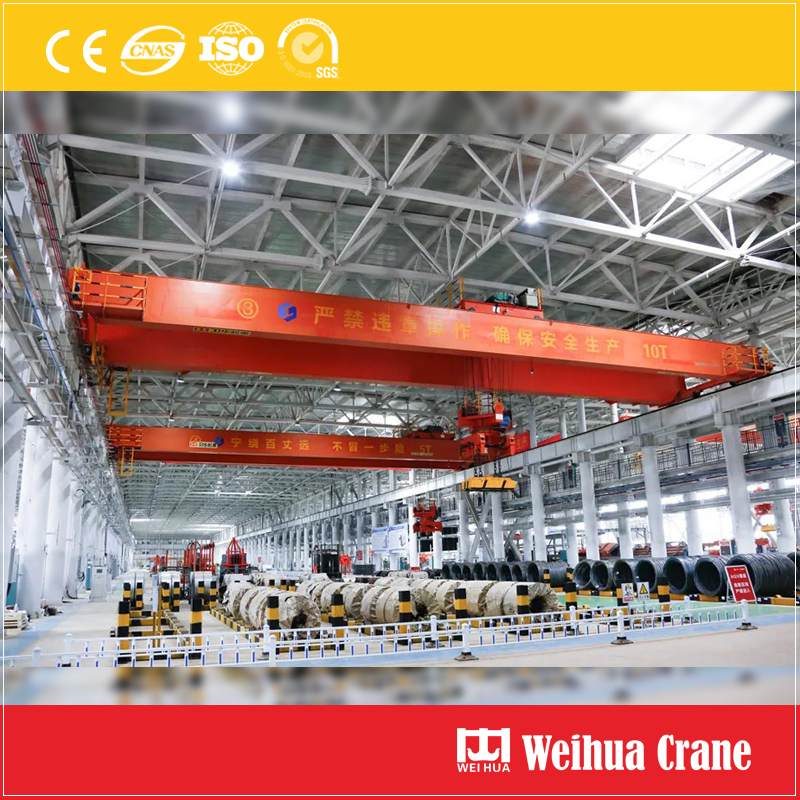

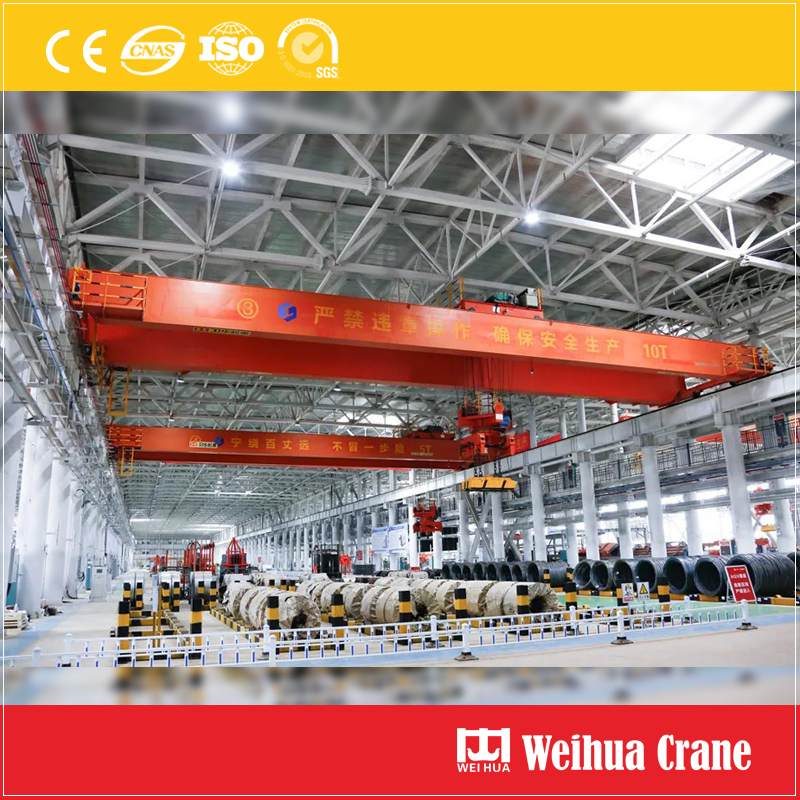

Intelligent Electromagnetic Crane Handling Steel Bars at Unmanned Plant

With the continuous development of the China Manufacturing 2025 plan, unmanned plants emerge in large numbers. Weihua intelligent handling equipment are also increasing. Now Weihua take you to an unmanned plant in Guangxi Province to take a look at the real-time working of Weihua's multifunctional intelligent unmanned crane handling steel bar.

The Guangxi Engineering Technology Research Center adopts big data management and integrated applications, making it the premier unmanned plant in the construction industry. Weihua intelligent unmanned magnet crane operation is an important part of the deep combination of Internet + smart manufacturing in the construction industry.

Features:

1. Automated systems developed by Weihua independently, with electric anti-sway system and automatic precise positioning functions;

2. Spreader replacement: Automatically replace the spreader according to the task;

3. Automatic lifting out and lifting in: (1) Into warehouse: Automatically identify the material unloading truck to the raw material storage area according to the list; (2) Out warehouse:

According to the loading task, it can automatically feed to the corresponding feeding point;

4. Transshipment: Automatically transfer finished semi-finished materials to the transfer point or AGV according to the transfer task;

5. Laser scanning: After the truck is put into place, it will automatically scan to identify incoming materials, and send out positioning coordinates to realize automatic unloading.

The multifunctional intelligent unmanned magnet crane is just a microcosm of the intelligent and high-end industrial manufacturing. Weihua will continue to increase its innovation and R&D to provide more intelligent handling equipment and solutions for various industries to help more intelligent unmanned plants.

Email: weihua@craneweihua.com

The Guangxi Engineering Technology Research Center adopts big data management and integrated applications, making it the premier unmanned plant in the construction industry. Weihua intelligent unmanned magnet crane operation is an important part of the deep combination of Internet + smart manufacturing in the construction industry.

Features:

1. Automated systems developed by Weihua independently, with electric anti-sway system and automatic precise positioning functions;

2. Spreader replacement: Automatically replace the spreader according to the task;

3. Automatic lifting out and lifting in: (1) Into warehouse: Automatically identify the material unloading truck to the raw material storage area according to the list; (2) Out warehouse:

According to the loading task, it can automatically feed to the corresponding feeding point;

4. Transshipment: Automatically transfer finished semi-finished materials to the transfer point or AGV according to the transfer task;

5. Laser scanning: After the truck is put into place, it will automatically scan to identify incoming materials, and send out positioning coordinates to realize automatic unloading.

The multifunctional intelligent unmanned magnet crane is just a microcosm of the intelligent and high-end industrial manufacturing. Weihua will continue to increase its innovation and R&D to provide more intelligent handling equipment and solutions for various industries to help more intelligent unmanned plants.

Email: weihua@craneweihua.com

订阅:

博文 (Atom)

.jpg)