The rubber tire track laying crane is more advanced than the traditional track-laying technology. It can be used to lift the tracks with two sets of cranes and carry the tracks into the tunnel for track laying. At the same time, it can be also used to lifting concrete tanks and with casting function.

The ballastless track project of the Israeli tunnel is an important project of the Tel Aviv light rail project. It is the largest government-licensed infrastructure construction project in Israel with the largest investment scale, complicated construction and large technical difficulty.

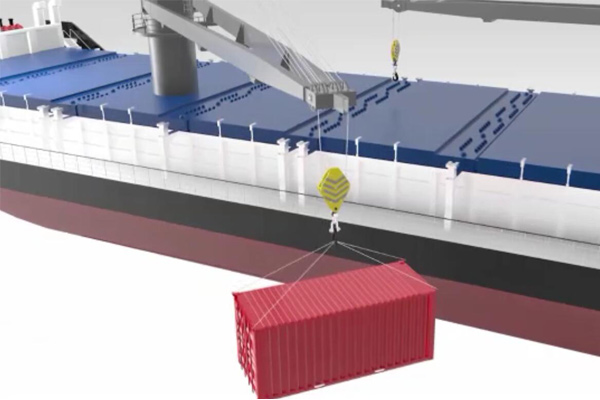

The traditional track laying method: firstly lay a temporary auxiliary track for the track laying machine and the concrete pouring car, and then lay the railway track by the track laying machine; after the construction of the concrete pouring car is completed, the temporary auxiliary track is removed. The process is complicated, a lot of equipment is used, and the construction period is long.

The advanced track laying method: the tire-type track laying crane has the functions of laying track and pouring concrete, and does not need temporary track, requires less construction equipment, saves labor and time.

The whole foundation of the ballastless track can replace the loose gravel bed track, which has the advantages of good smoothness, high stability, long service life and less maintenance work. The train can run at speeds of more than 350km/h, which is the world's advanced track technology.

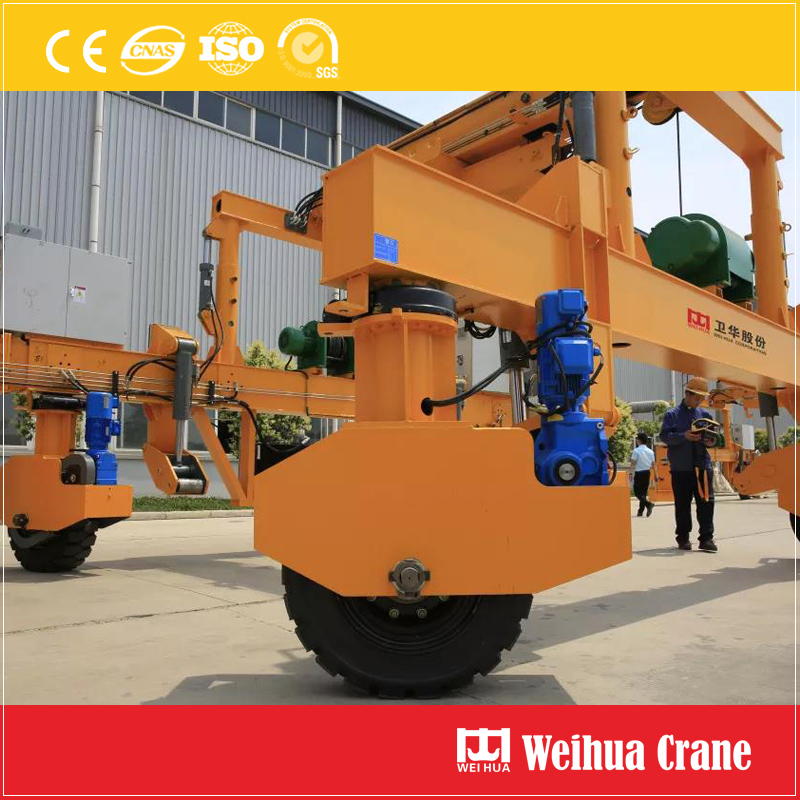

Features of Rubber Tire Track Laying Crane:

1. Modular design, convenient transportation and installation.

2. The gantry lifting, variable pitch, steering, and concrete tank lifting are all controlled by electro-hydraulic control, stepless speed regulation, and each action can be performed separately or in combination.

3. The concrete tank clamping mechanism is equipped with high-quality synchronous valve and safety valve, and the synchronization accuracy is over 98%.

4. Walking frequency control, all-wheel drive, high stability, strong ground adaptability.

5. One-button to control all-wheel steering and rail change, steering mechanical limit, straight travel lock and other functions, practical and efficient.

6. Handle and remote control, interlocking functions, safe and reliable.

Email: weihua@craneweihua.com

.jpg)