In response to the serious car parking problem,

This vertical circulation car parking system mainly consists of main steel structure, plate structure, transmission system, control system, and safety protection device. The main structure is internally provided with a fixed guide rail, the lifting chain roller runs in the guide rail, and the carriage plate is suspended on the extended plate of the lifting chain. During operation, the car is parked inside the carriage board, and the chain drive system drives the carriage board for circulation running in the vertical direction. When the carriage board runs to the lowest end, the vehicle can be accessed.

Auto parking system will be easily find in city enterprises, institutions, public places, scenic spots, residential quarters, etc. Drivers no longer have to worry about the parking spaces!

Features and Advantages:

a. 2 parking spaces for 12 cars, maximized utilization rate of available space;

b. Takes average 70 seconds and up to 120 seconds to park or take your car, the vacancy plate is always at the lowest floor, efficient and convenient;

c. Automatic control, PLC, Frequency Control, less impact to equipment;

d. Use alone or in combination;

e. Simple operation, 4 ways to use it, card, buttons, remote control, mobile phone, App, etc.

f. Safe and reliable, If people approach, the equipment will automatically stop running;

g. Economical, short construction period, less consumption, green, nice appearance;

h. Quick installation and removal;

i. Stable and durable, main PLC and electrical components are from Siemens, Schneider, Omron;

j. Good market prospects;

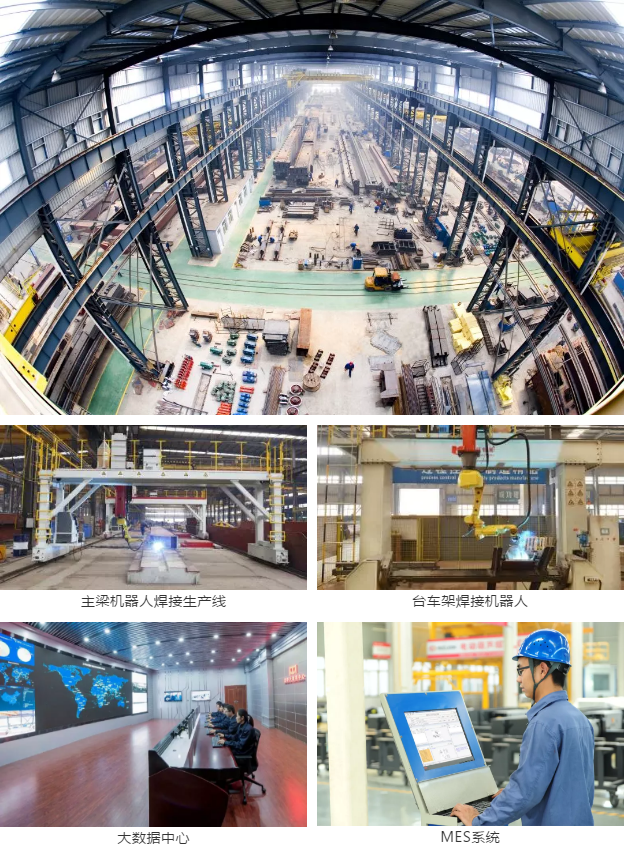

k. Weihua Smart Garage adopts advanced parametric design methods such as 3D CAD and CAE;

l. Supported by international first-class brand drive motor;

m. Automated line to ensure structural stability;

n. Strict quality assurance system provides users with safe and reliable products and services;

o. Overall structure is designed by dynamic simulation analysis to ensure that the equipment is safe and reliable throughout its life cycle;

p. Each component has a feature code to make product quality can be reversed;

q. It uses intelligent license plate recognition technology, IC control technology, computer image processing and other advanced technologies to realize all-round management of vehicle parking guidance, fee collection, etc.

r. The core control technology and safety detection device can efficiently protect people and vehicles;

s. The intelligent frequency control technology makes the garage run smoothly and efficiently;

t. Using autonomous positioning technology to make the access faster;

u. It adapts to the different needs of customers by setting the operating modes simply on the operation panel;

v. LOT for smart parking can connect parking equipment, charging systems, etc. to the Weihua cloud platform to achieve big data transformation of traditional parking management systems integrating the function of charging, reservation, online payment, etc. Bring a better parking experience to users.

w. Weihua smart garage can be installed in banks, hospitals, supermarkets, residential areas, enterprises and institutions, tourist areas, etc. with small footprint, large capacity, easy to install and move. Realizing that the capacity is 5-10 times than that of parking on the ground;

x. Mobile charging piles can be installed as needed to provide charging services for new energy vehicles;

y. Overall planning and scientific customization according to the surrounding environment.

Email: weihua@craneweihua.com

.jpg)

.jpg)