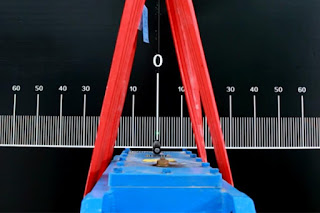

The boat and yacht handling crane includes the following items: main structure, traveling wheel block, hoisting mechanism, steering mechanism, hydraulic transmission system and electric control system. The main structure is N type, which can transfer the boat/yacht with height surpass crane's height.

According to different requirements of our customers, the boat handling crane can handle different tonnage boats or yachts (10T-800T) from the shore side, it can be used for the maintenance on the shore side or can put the new boat into the water. This yacht handling crane has soft and firm belt to lift the boat and yacht so that it will never hurt the surface. This crane also can put the boat in sequence quickly with small gap between each two boat.

Email: kay@craneweihua.com

|

| boat and yacht handling crane |