The

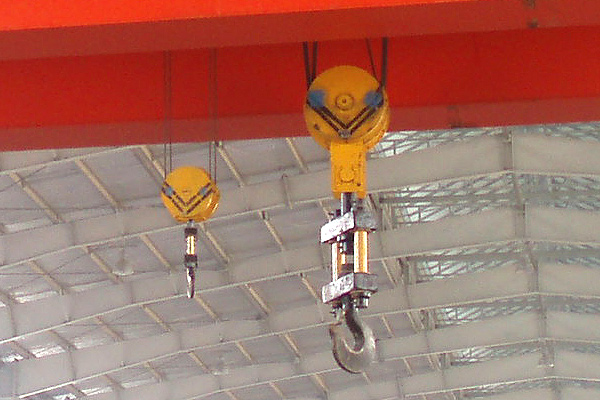

motors for cranes are of various famous brands from China and other countries. For your different needs, we provide different option motors brands such as Jiamusi, Jiangxi Special Motors, Siemens, ABB, SEW, etc. We suggest the right brand motors and models according to the

cranes you have. Such as ZDS Motor for

MD hoist and ZDY motor for electric hoists.

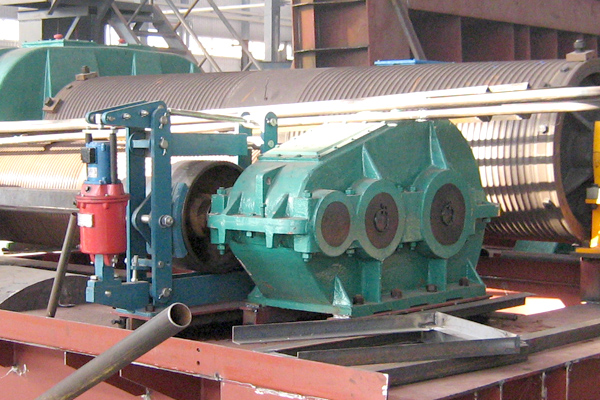

ZDS Motor:

1. Application scope: MD Hoist

2. ZDS double speed motor cluster is a composite motor which is combined by a low speed drive device between two awl rotor three-phase asynchronous motors.

3. The high-power one is the main motor, and the low-power one is the auxiliary motor. That makes ZDS has two mode of speed: high and low.

4. ZDS is a horizontal type motor, its seat is without foot, and it utilizes cone brake.

5. It's able to start frequently.

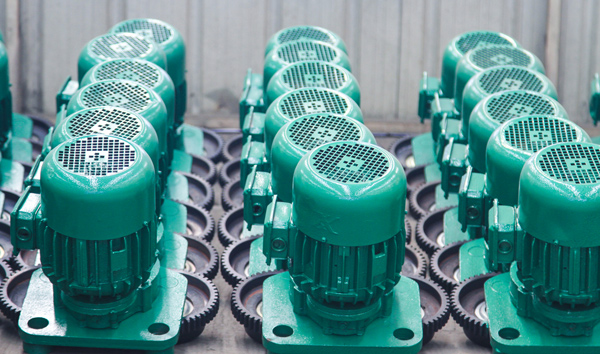

ZDY Motor:

1. Application scope:

Electric hoists2. Conical rotor three-phase asynchronous motor.

3. Utilizing automatic brake device.

4. Applies to

trolley traveling with electric hoist and crane traveling mechanism.

5. Applies to the drive device that needs small starting torque and smooth brake.

6. It's self-cooled type, and its front cover connects flange.

7. Stator: good moisture-proof performance and thermal stability, and its insulation class reaches B class.

8. Rotor: Running smoothly, small vibration.

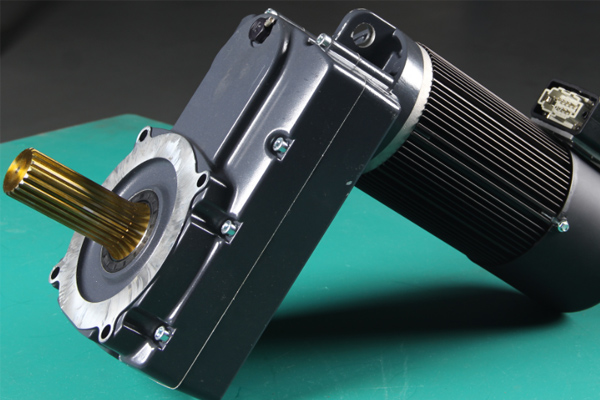

Electric Hoist Motor

Electromagnetic Brake Solid Rotor 3-phase Asynchronous Motor

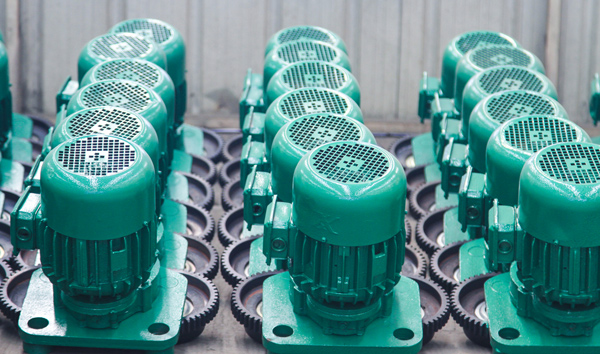

Motors for Monorail Hoist Trolleys

Email: weihua@craneweihua.com

WhatsApp: +86 15093392066

.jpg)